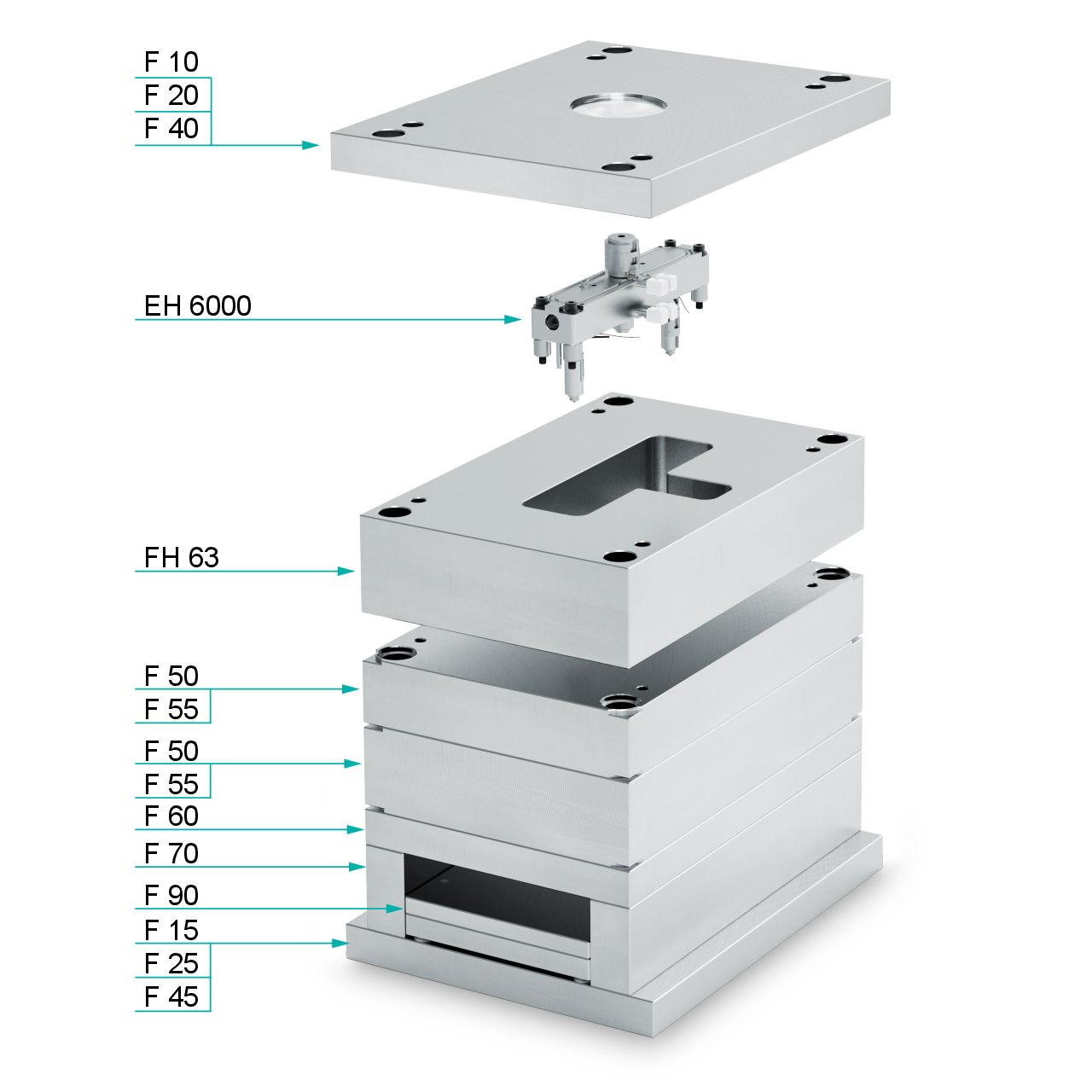

A hot runner mould in just 5 minutes

The Meusburger hot runner mould consists of a complete mould base including a hot runner system. The major advantage for you is the specially developed configurator, which allows for savings in time as well as price transparency.

Information

Information

- Hot runner system EH 6000: delivered completely machined and assembled

- Manifold plate FH 63: delivered including milled recesses for the manifold

Technical documents

Technical documents

Here you will find the relevant technical documents for your standardised hot runner system.

Data sheets

We are happy to provide you with the data sheets for our variety of hot runner manifolds.

Configurator for hot runner moulds

A complete hot runner mould in just a few clicks

The configurator for hot runner moulds is the optimal tool for all designers. With just a few clicks, you get the complete mould base including the hot runner system in the usual high quality. Of course, the 3D data is available for download as usual. The advantages are plain to see. The designer can concentrate on other matters during the mould design and thus saves valuable time and costs.

Your benefits at a glance:

- Easy and fast configuration of the hot runner mould

- High flexibility through individually adjustable nozzle positions

- Live display of the manifold and 3D data immediately available

- Transparent costs due to immediate price display

- Short lead times of the configured components

Special solutions

Special solutions

For special solutions, please get in touch with your contact person at Meusburger. You can find your contact person via the contact search.

Configurator update

With our mould making update, we also added innovations for configurator for hot runner moulds. We considerably expanded our range of nozzles as well as the selection of plastic materials.

Reference customers

Satisfied Meusburger customers

A number of customers have already expressed their satisfaction with our hot runner moulds. You can find an extract from our list of customers and some information about our projects in a separate overview.

Technical inspection of hot runner components

Technical inspection of hot runner components

Both standardised hot runner systems such as the hot runner mould and customised projects can be inspected by the hot runner support team. A form is available in the Meusburger shops which serves as a basis for this inspection process.

Sprue cost calculator

Long-term cost reductions through the use of a hot runner system

Hot runner or cold runner? This is a frequent question to which we are pleased to help you find an answer. You will see that a hot runner system will be the better choice in the long run.

Free expertise

Our experts have worked intensively on this topic. After a quick and easy registration, we will gladly share our know-how with you in our free white paper.

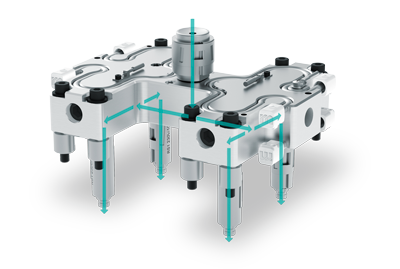

4 variations – the choice is yours

With our standardised hot runner moulds, you have the choice between four different manifold series.

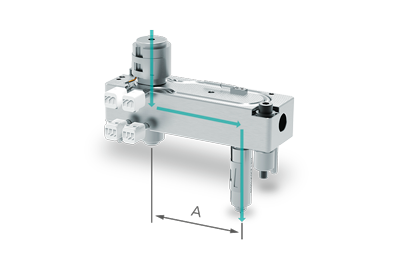

IMT1

Deflection manifold with 1 nozzle

Possible hole patterns (A):

- min. 37.5 mm

- max. 206.25 mm

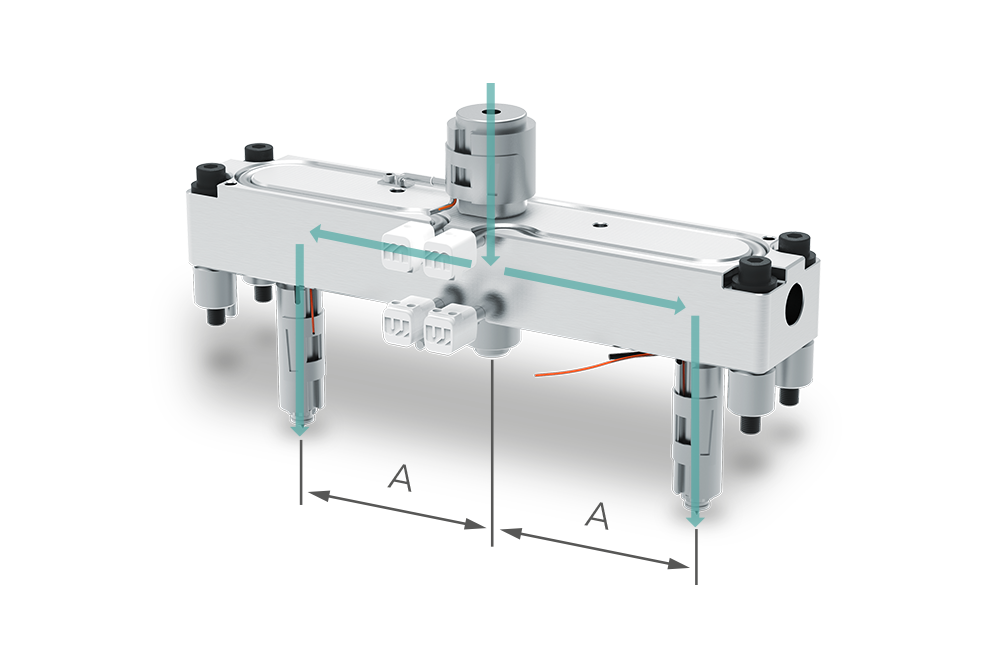

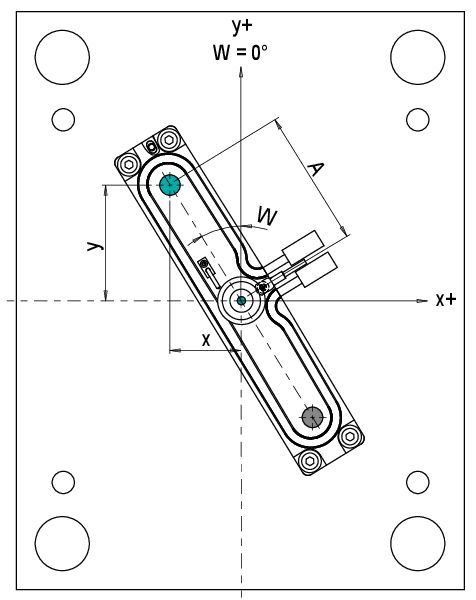

IMT2

In-line manifold with 2 nozzles

Possible hole patterns (A):

- min. 25.0 mm / 37.5 mm (d 37)

- max. 206.25 mm

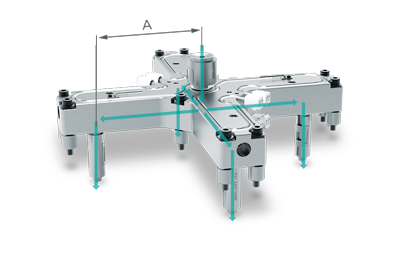

CMT4

Cross manifold with 4 nozzles

Possible hole patterns (A):

- min. 35.5 mm

- max. 220.5 mm

HMT4

H manifold with 4 nozzles

Possible hole patterns:

- L1: 40,0 – 210,0 mm

- L2: 25,0 – 206,25 mm

- L2: 37,5 – 206,25 mm (d 37)

Hot runner system EH 6000

Hot runner nozzle, smartFILL, screw-in type EH 4100

- Including gate assembly EH 4200 / RT, EH 4240 / RT-D, EH 4245 / RT-DL, EH 4250 / RT-DC

- Heater: 230 V; cable length: 2000 mm

- With integrated thermocouple Fe-CuNi (type J), DIN 43710, black+/white−

- Maximum injection pressure: 1800 bar

Sprue bush for hot runner manifold EH 6400

- With integrated thermocouple Fe-CuNi (type J), DIN 43710, black+/white−

- Heater: 230 V; cable length: 2000 mm

Manifold EH 6100

- Available in material grades 1.2311 / 1.2316 depending on the plastic used

Flexible tubular heater EH 5030

- Power: 700–2800 W, depending on manifold size

Centring piece EH 6200

- Positions the manifold in the mould centre opposite the sprue bush

90° bent thermocouple EH 5200

- Fe-CuNi (type J)

- Thermocouple with kink protection spring

- Connector length: 5000 mm

Grounding cable EH 5225

- Connector length: 2500 mm

Connection terminal EH 5220

Connector clamp

- Allows a screwable connection of the electrical supply lines to any flexible heater

- Two clamping options provided on each connector clamp, so that by attaching a ‘bridge’ the flexible heater can be connected in parallel directly at the heating outlet

Connecting cable

- 2.5 mm² pure nickel cable, with glass fibre insulation, 4-fold up to 300 °C

Spacer screwing set EH 6214

- For the correct position and for screwing in the manifold

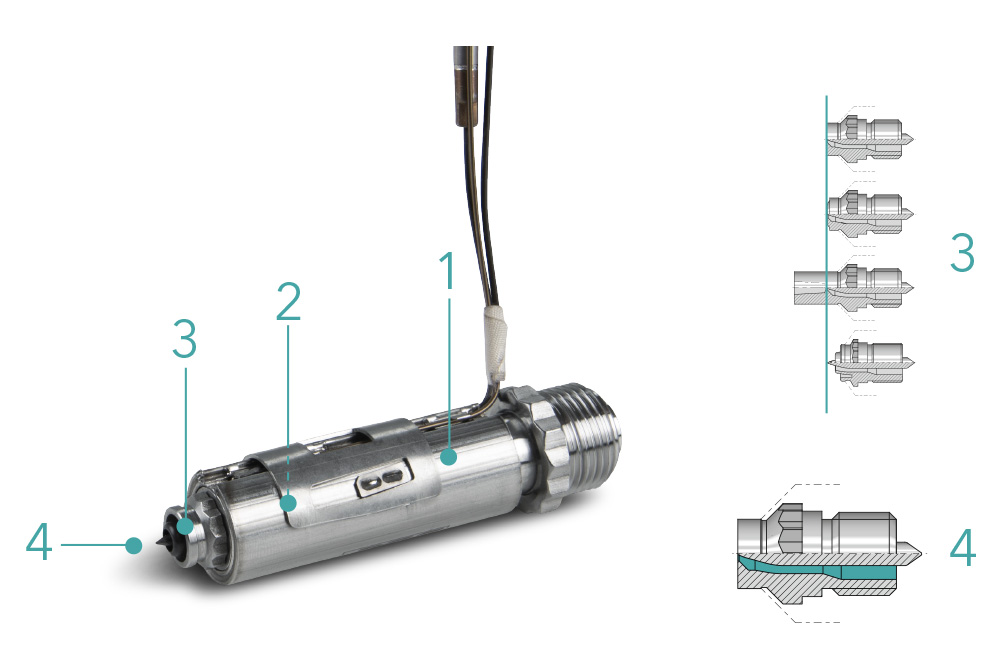

Hot runner nozzle EH 4100

1 – Innovative heating technology

- Optimal heat transfer into the plastic used

- Homogeneous temperature profile on the entire nozzle length through differentiated power distribution

- Easy and fast change of heater and thermocouple due to intelligent clip lock

2 – Streamlined melt channel with high-quality surface

- Optimal melt exchange since there are no dead spots

- Low shear stress of the melt

- Good colour-changing qualities

3 – Different gate types

- Flexible adjustment of the hot runner nozzles to different applications and materials

- Easily exchangeable, highly wear-resistant gate assemblies

- Consistent nozzle lengths (l dimension) for different types of gates

4 – Nozzle tip for optimal flow properties

- Partitioning and re-merging of the melt in the hot area of the nozzle

- Reduction of flow line development

- Better optical and mechanical quality of the parts

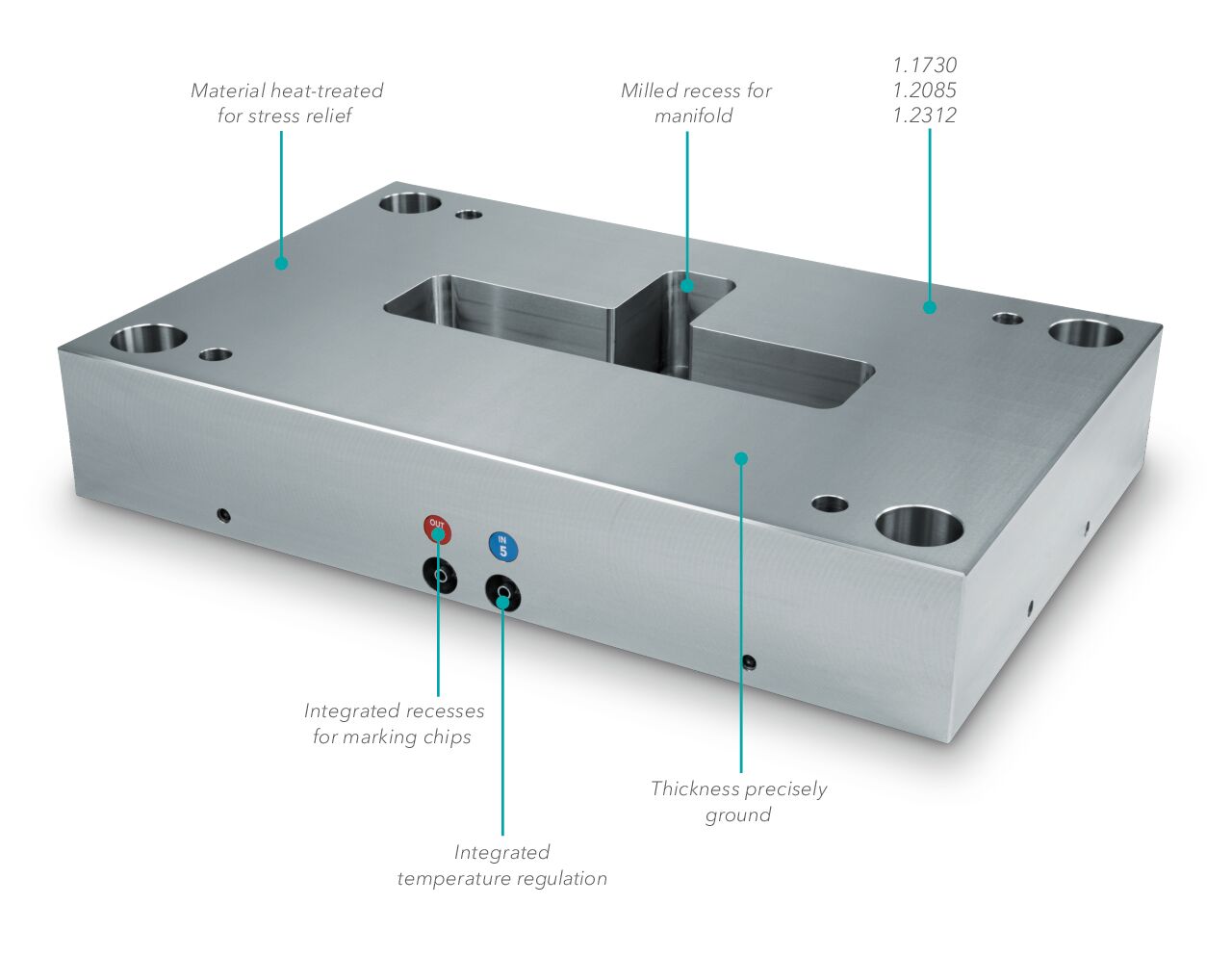

Manifold plate FH 63

The manifold plate FH 63 is automatically created by entering the parameters in the configurator. Width and length can be selected by the user, the thickness is generated automatically and precisely ground to ± 0.01 mm. Mould sizes from 216 x 246 to 796 x 1196 can be selected.

The 3D model already has the appropriate recesses for the hot runner system. Furthermore, three different material grades are available: 1.1730 tool steel, 1.2085 tool steel, and 1.2312 tool steel.

Marking

Marking

Plastic marking chips can be used for identifying the temperature regulation components.

Gate assemblies EH 42..

4 different nozzle tips for the right gate type

EH 4200 / RT

Gate assembly, smartFILL ring gate

EH 4245 / RT-DL

Gate assembly, smartFILL ring gate, plunging with extension

- With extension on the centring head

- Gating to free-form surfaces

- Adjustment to the product’s geometry

- Sprue scrap with scrap cone

- Suitable for all thermoplastics with a medium to narrow processing window, including filler material and reinforcing fillers

- Nozzle tip and centring head are highly wear-resistant and replaceable

EH 4250 / RT-DC

Gate assembly, smartFILL ring gate, plunging with calotte

Gate type and diameter

You can find further information on the selection of the right gate type and the design of the gate diameter in our brochure.

Delivery

The hot runner system is completely assembled and tested. The mould base for the hot runner mould is not pre-assembled, as in its standard version. Thus, valuable time can be saved by not having to take it apart and the components are available much faster for subsequent machining.

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

Ελλάδα [EL]

Ελλάδα [EL]

华 [ZH]

华 [ZH]