Contato

Estamos sempre disponíveis de segunda a sexta-feira, das 8:00 às 17:00. Utilize esta ligação para encontrar as suas pessoas de contacto consoante a sua região.

Sede em Wolfurt

+43 5574 6706-0

Carrinho de compras {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Artigos Mudar carrinhos de compras

Observação

| Imagem | Artigos | Unid. | Preço individual | Preço total | Preço total, incl. desconto | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Clientes

- Mould making

- Die making

- Construção de máquinas e gabaritos

- Projetistas

- Moldes de injeção

-

Produtos

- Artigos Novos

- Estruturas standard

-

Estruturas para cunhos e cortantes

- Placas SV para cunhos e cortantes

- Placas SP para cunhos e cortantes

- Placas para estruturas SH com duas guias, guiamento traseiro

- Placas para estruturas SD com duas guias, guiamento na diagonal

- Placas para estruturas SZ com duas guias, guiamento central

- Plates for SM-modular concept

- CONJUNTOS DE FORMAÇÃO

- Sistema de fixação H 3000

- Placas P

- Barras N

- Placas e barras

- Maquinação Especial

- Acessórios E

- Sistemas de canais quentes

- Controladores de temperatura

- Equipamentos e consumíveis

- Empresa

- Recrutamento

- Serviço

We are your partner for every project phase.

A sua ideia de produto – a nossa solução

Há mais de 60 anos que os nossos sistemas de canais quentes respeitam os requisitos de aplicações exigentes em termos de propriedades físicas, materiais, integração funcional, qualidade de superfície e designs especiais. Encontrará connosco a solução de canais quentes certa.

Sistemas de canais quentes personalizados

Sistemas de canais quentes normalizados

Apio e assistência

Desde a fase de engenharia e design até à colocação em funcionamento e à manutenção, a nossa equipa fornecerá um suporte abrangente. Recebe feedback em todas as fases do projeto no prazo de 24 horas. Mediante pedido, os nossos especialistas verificam os seus projetos e garantem que poderá alcançar a otimização desejada no processo de moldagem por injeção, diferentes materiais e conceitos de molde.

Indústrias

Packaging

Whether large quantities of caps and closures or diverse packaging: we offer suitable hot runner solutions for the packaging industry to make the production process efficient and achieve maximum plant profitability. We support you in the production of attractive, functional and sustainable plastic parts.

- Item: flip top

- Material: PP

- Part weight: ≈ 2 g

- Wall thickness: ≈ 1 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 16-drop

- Item: blank plug

- Material: PP+TPE

- Part weight: ≈ 2 + 0,8 g

- Wall thickness: ≈ 3 mm

- Hot runner system: smartFILL RT

- Number of cavities: 8 + 8-drop

- Particularity: multi-component technology

- Item: cap

- Material: PP

- Part weight: ≈ 2 g

- Wall thickness: ≈ 1,5 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 24-drop

- Item: cap

- Material: PE LD

- Part weight: ≈ 2 g

- Wall thickness: ≈ 1 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 24-drop

- Item: tube shoulder

- Material: PP

- Part weight: ≈ 2 g

- Wall thickness: ≈ 1,5 mm

- Hot runner system: smartFILL RT

- Number of cavities: 16-drop

Requirements

- Quick colour changes

- Short cycle times

- Perfect surface quality

- Attractive product designs

- Sustainable materials

Matching products

Medicine

Dimensional accuracy, precision, reproducibility, clean room applications: especially for the most demanding applications in the medical industry, our hot runner solutions ensure high process reliability and a perfect result for your plastic parts.

- Item: catheter

- Material: PA12

- Part weight: 4 g

- Wall thickness: 5 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 2-drop

- Item: syringe piston

- Material: PP

- Part weight: ≈ 1 g

- Wall thickness: ≈ 1 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 24-drop

- Item: mouthpiece for inhaler

- Material: PP

- Part weight: ≈ 2 g

- Wall thickness: ≈ 1 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 8-drop

- Item: dialyser cover

- Material: PC

- Part weight: 3,2 g

- Wall thickness: ≈ 1 mm

- Hot runner system: smartFILL RT

- Number of cavities: 16-drop

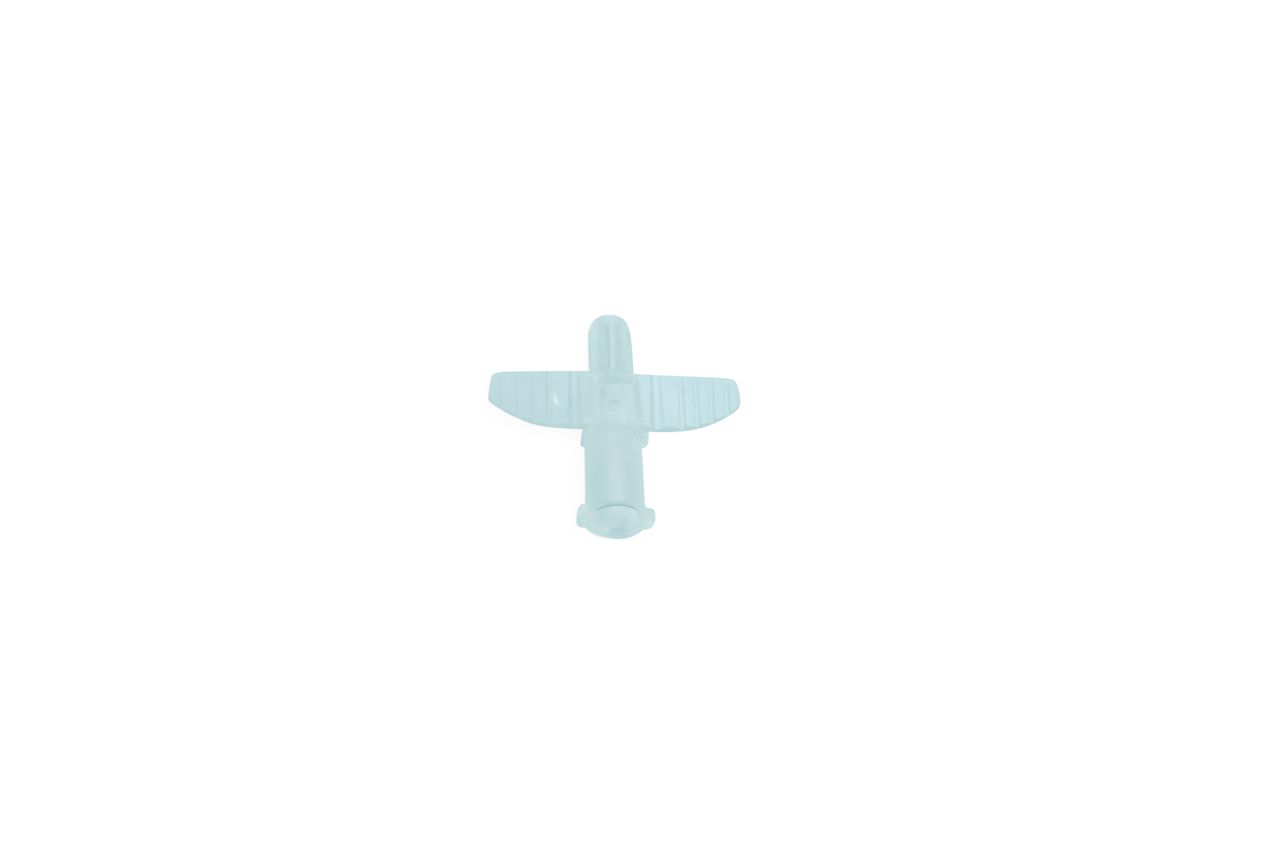

- Item: butterfly

- Material: PP

- Part weight: ≈ 1 g

- Wall thickness: ≈ 1 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 24-drop

Requirements

- Precision & dimensional accuracy

- Biocompatibility

- Sterilisability

- Long-term stability

- Neat feed points

Matching products

Transport

Pallets and carrier boxes have to withstand a lot: extreme mechanical stress, fluctuating temperatures or high UV radiation. Whether high shot weights, stack moulds or complex family moulds, we are happy to provide you with our accumulated application expertise in the field of hot runner systems.

- Item: folding box

- Material: PP

- Part weight: 1980 g

- Wall thickness: 2,5 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 1 + 2 + 2-drop

- Particularity: family mould

- Item: Eurobox

- Material: PP

- Part weight: 500–1900 g

- Wall thickness: ≈ 2 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 2-drop

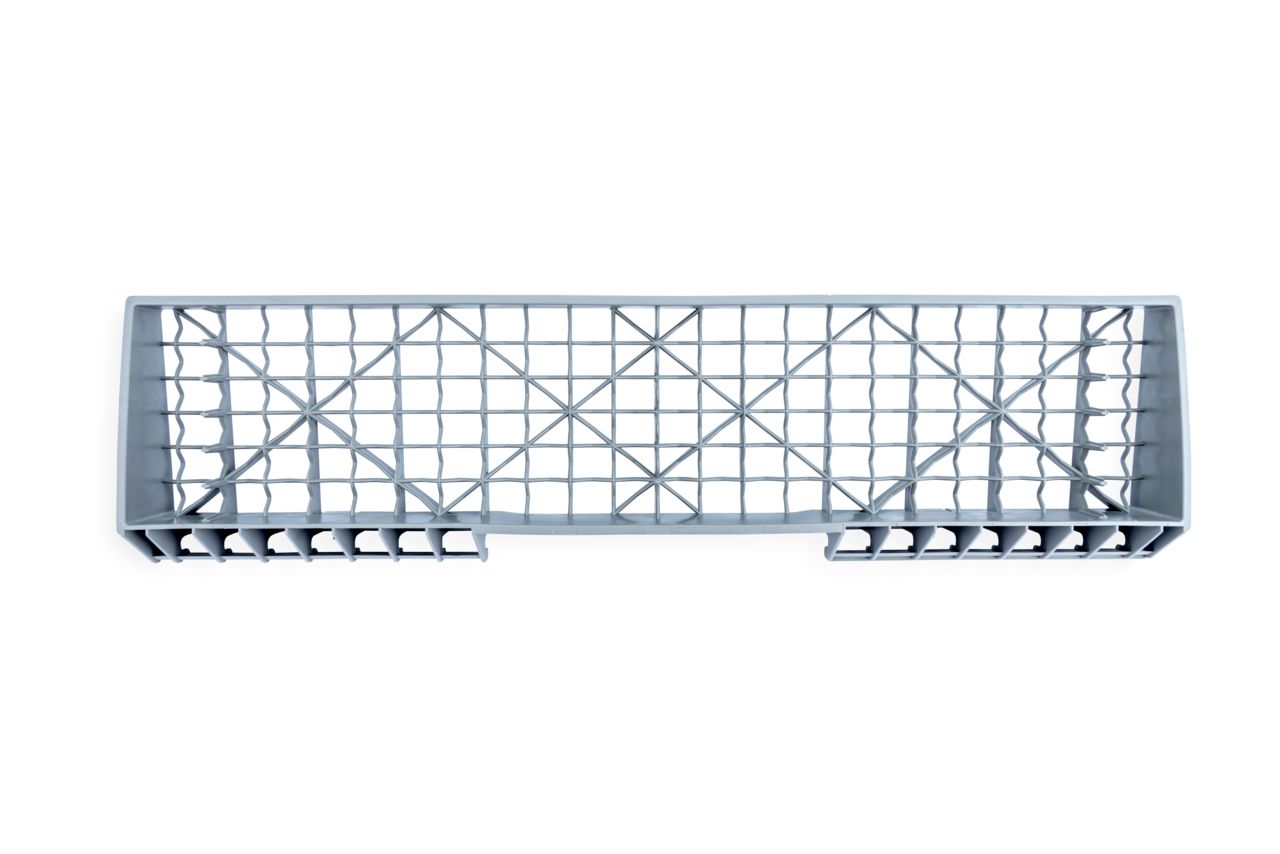

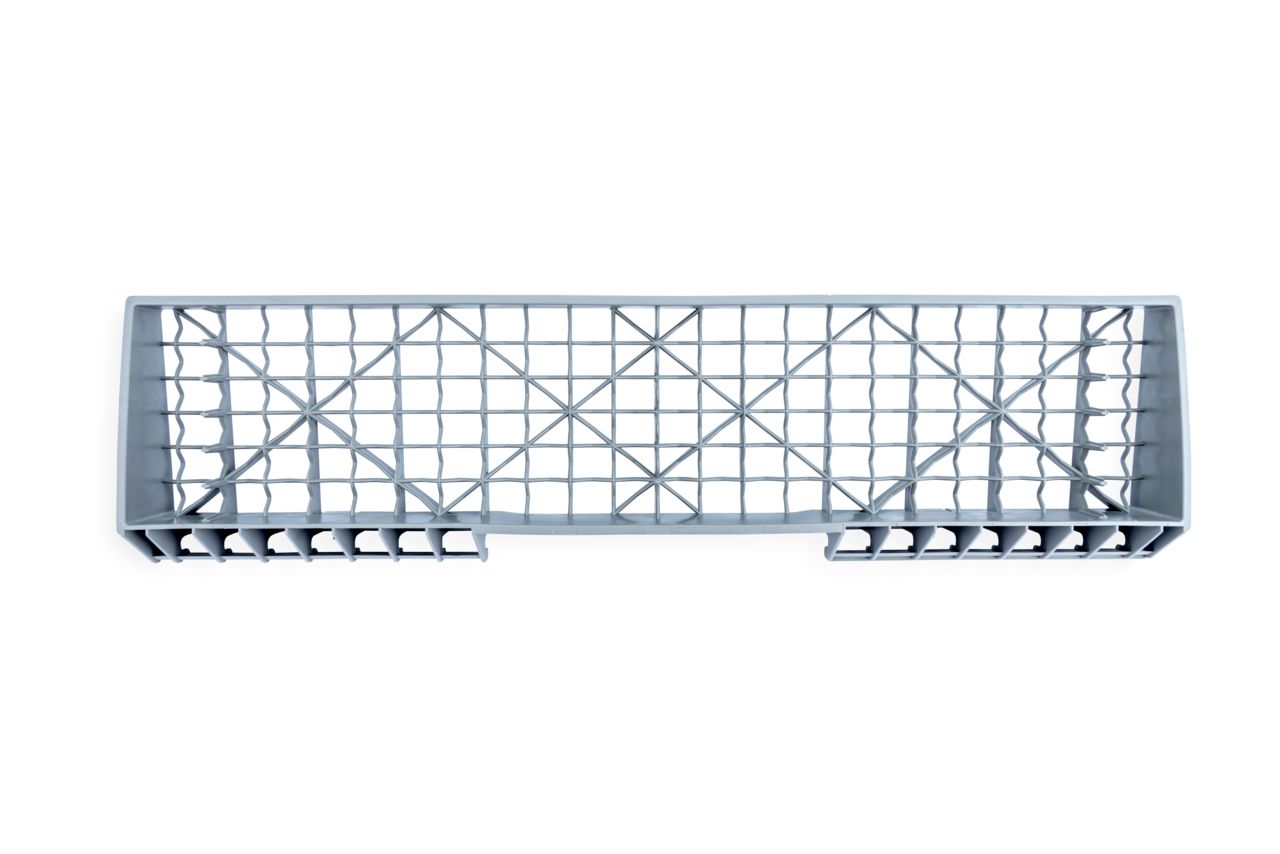

- Item: sorting box

- Material: PP

- Part weight: 300–1500 g

- Wall thickness: ≈ 2 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 2-drop

- Item: pallet

- Part weight: 15,000 g

- Wall thickness: ≈ 10 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 1-drop

Requirements

- Complex geometries

- High shot weights

- Mechanical durability

- In-mould labelling

- Stack moulds and family moulds

Matching products

Technical components

Technical components are used in innovative products and require a high degree of accuracy. Technical plastics and high-performance plastics with and without reinforcing fillers are predominantly used in order to ensure high load capacity and reproducibility of the products. We offer you precise valve gate technologies for optimal plastic part quality.

- Item: wall box + fuse cover

- Material: PS V0

- Part weight: 1425 g + 610 g

- Wall thickness: ≈ 2 mm

- Hot runner system: smartFILL RT

- Number of cavities: 1-drop each

- Item: connector housing

- Material: POM-H

- Part weight: ≈ 1–10 g

- Wall thickness: ≈ 1–2 mm

- Hot runner system: smartFILL RT

- Number of cavities: 16-drop

- Item: connector

- Material: LCP

- Part weight: ≈ 2 g

- Wall thickness: ≈ 0,8 mm

- Hot runner system: smartFILL RT

- Number of cavities: 8-drop

- Item: housing

- Material: POM-C

- Part weight: 7 g

- Wall thickness: ≈ 1,5 mm

- Hot runner system: smartFILL RT

- Number of cavities: 8-drop

- Item: cover

- Material: PC

- Part weight: 425 g

- Wall thickness: ≈ 2 mm

- Hot runner system: smartFILL EH 4050

- Number of cavities: 1-drop

Requirements

- High-performance plastics

- Filler material and reinforcing fillers

- Complex functions

- Good mechanical properties

- High reproducibility & durability

Matching products

Automotive

We are your reliable hot runner partner for the versatile requirements of the automotive industry. These include lightweight construction applications, visually sophisticated interior components or special multi-component parts in the field of vehicle acoustics. No matter what the requirements are, we develop the hot runner solution for your needs based on our many years of experience in the industry.

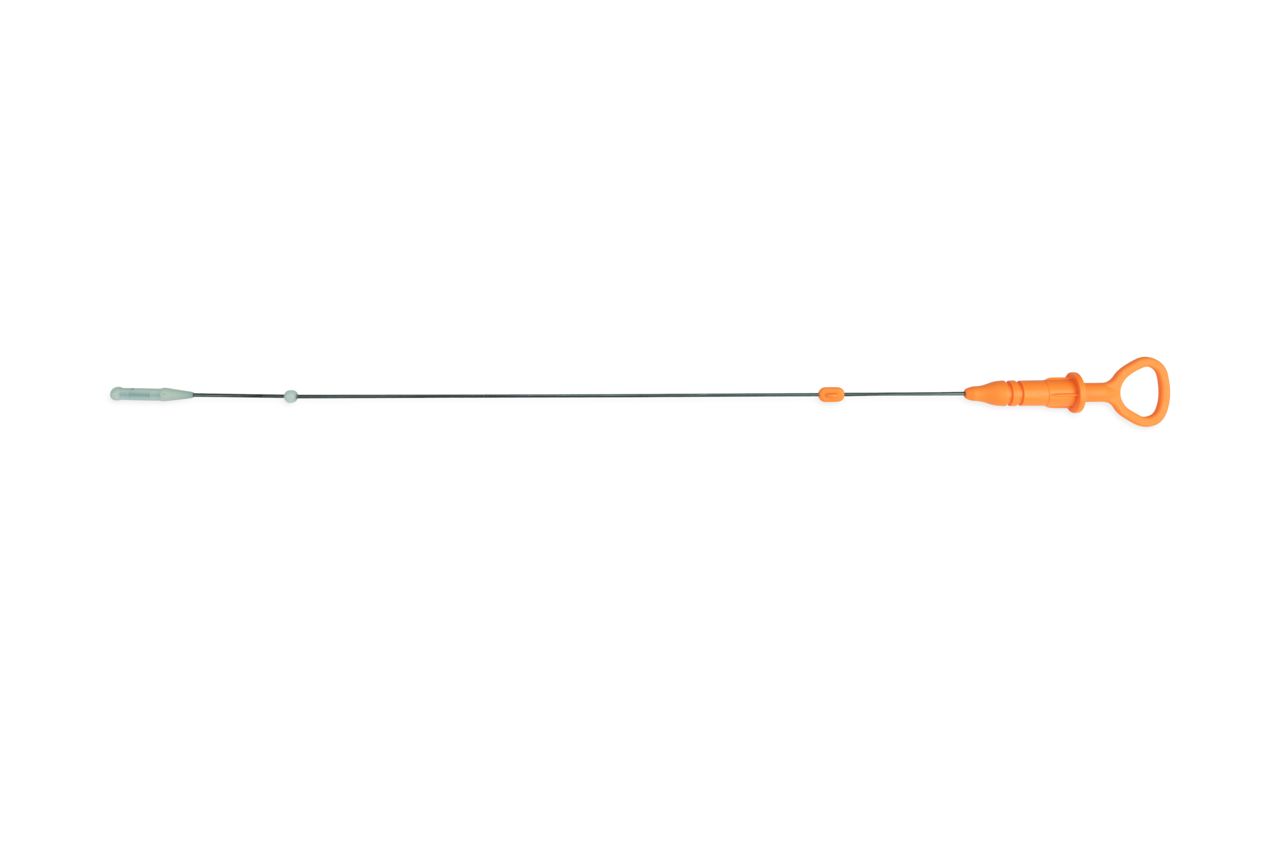

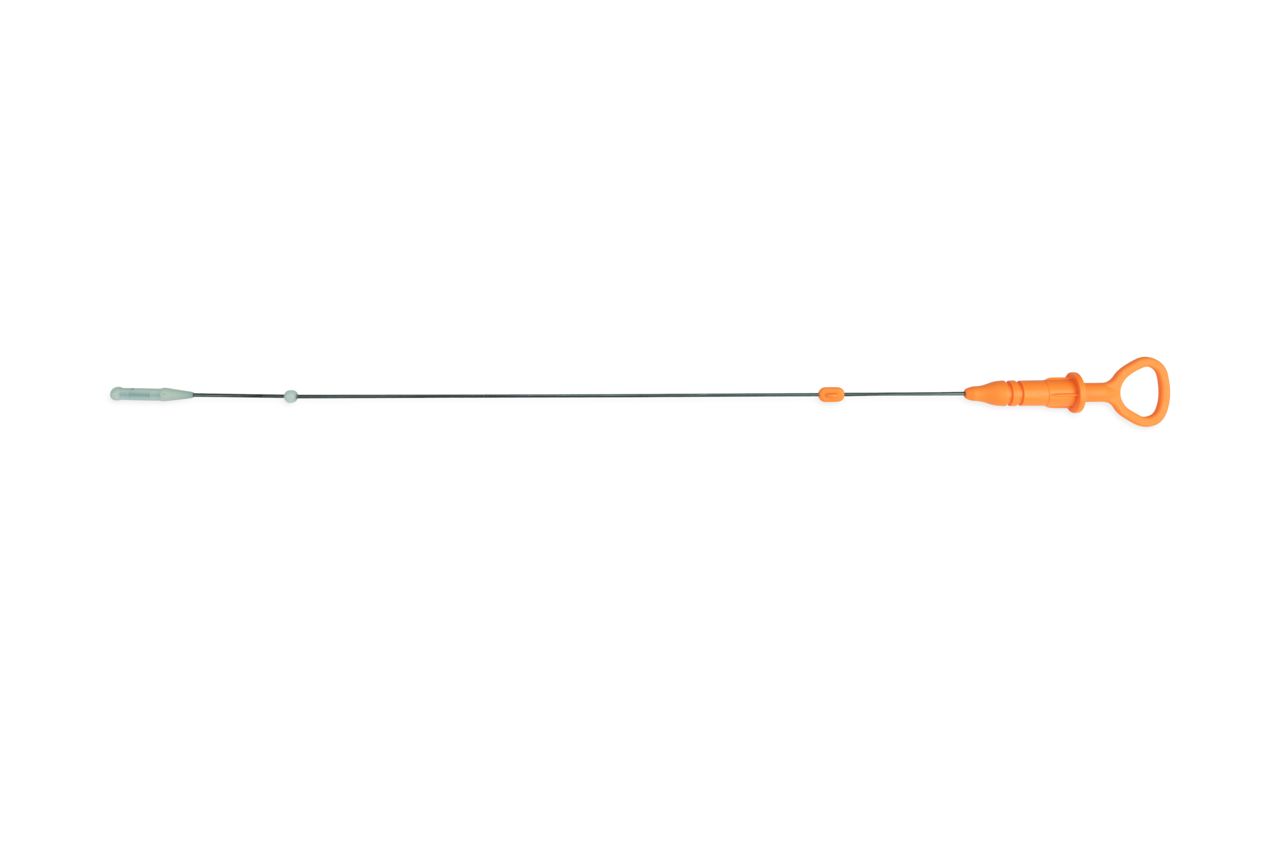

- Item: oil dipstick

- Material: PA6.6

- Part weight: ≈ 6 g + 2 g

- Wall thickness: ≈ 2–6 mm

- Hot runner system: smartFILL RT

- Number of cavities: 4 + 4-drop

- Particularity: metal overmoulding

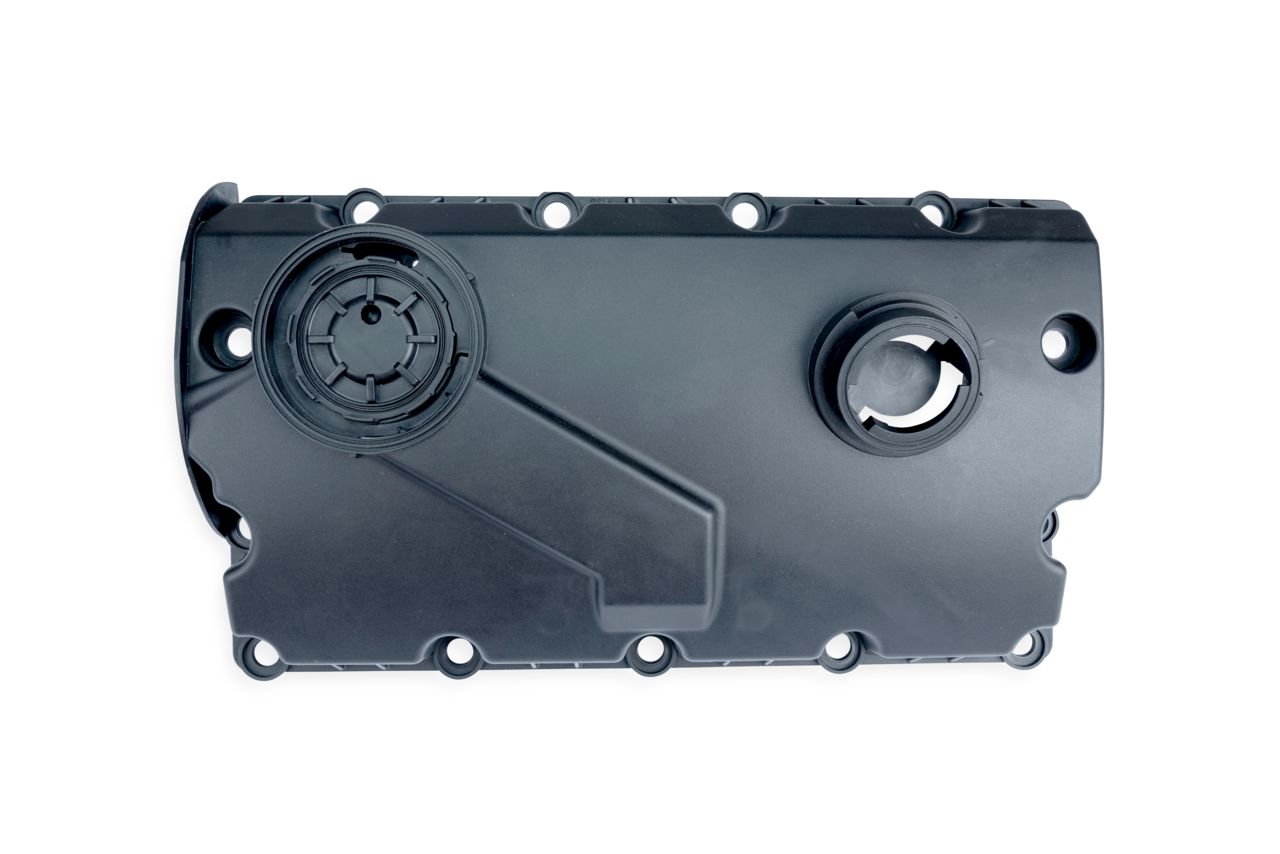

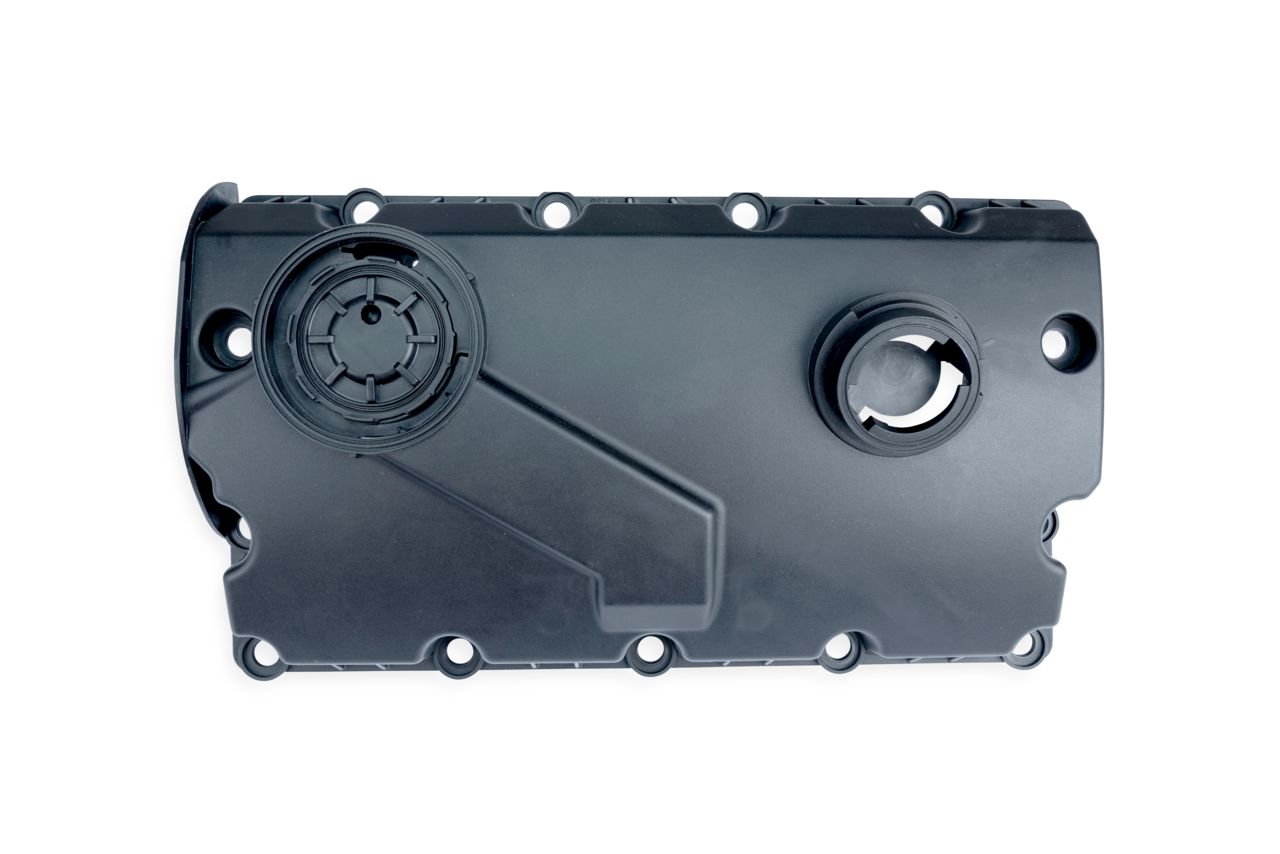

- Item: motor cover

- Material: PA6.6 GF35

- Part weight: 650 g

- Wall thickness: ≈ 3,5 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 4-drop

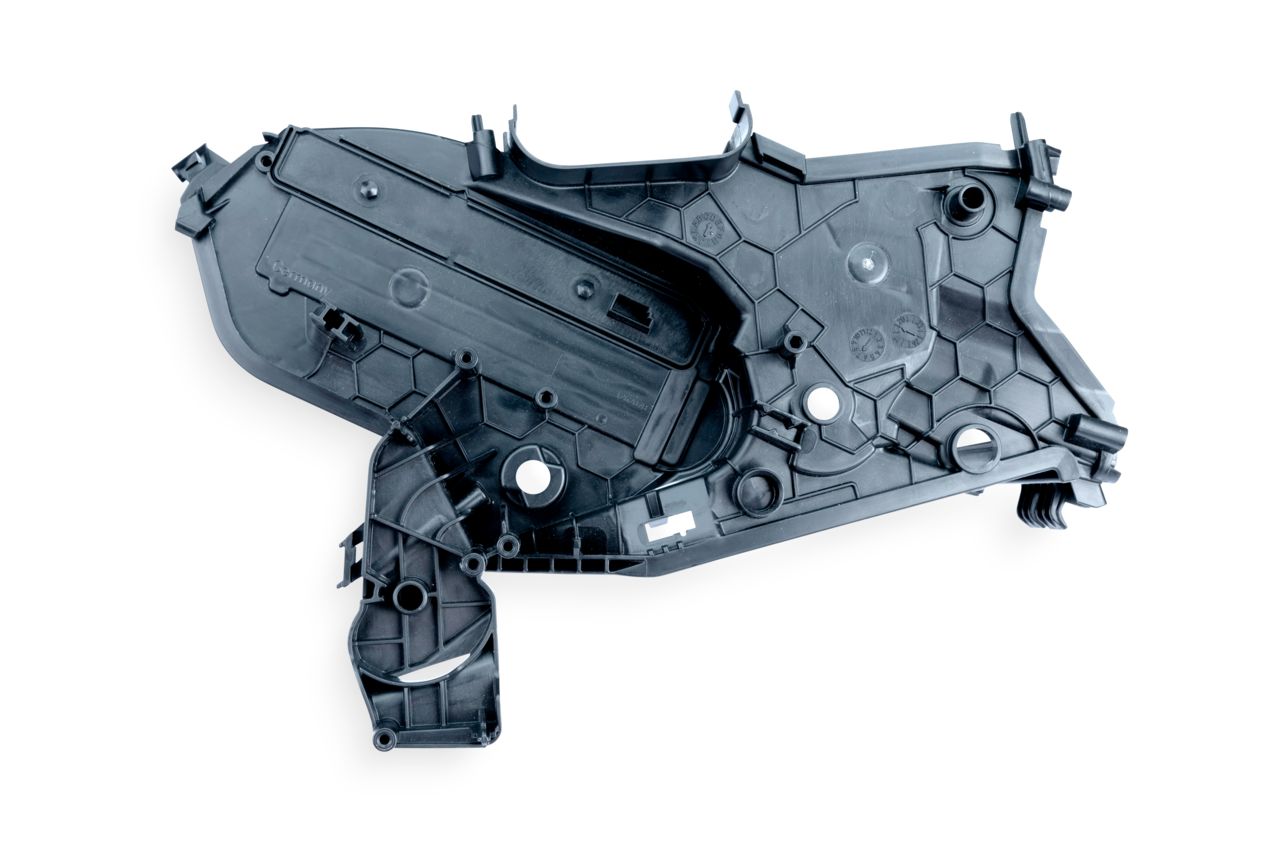

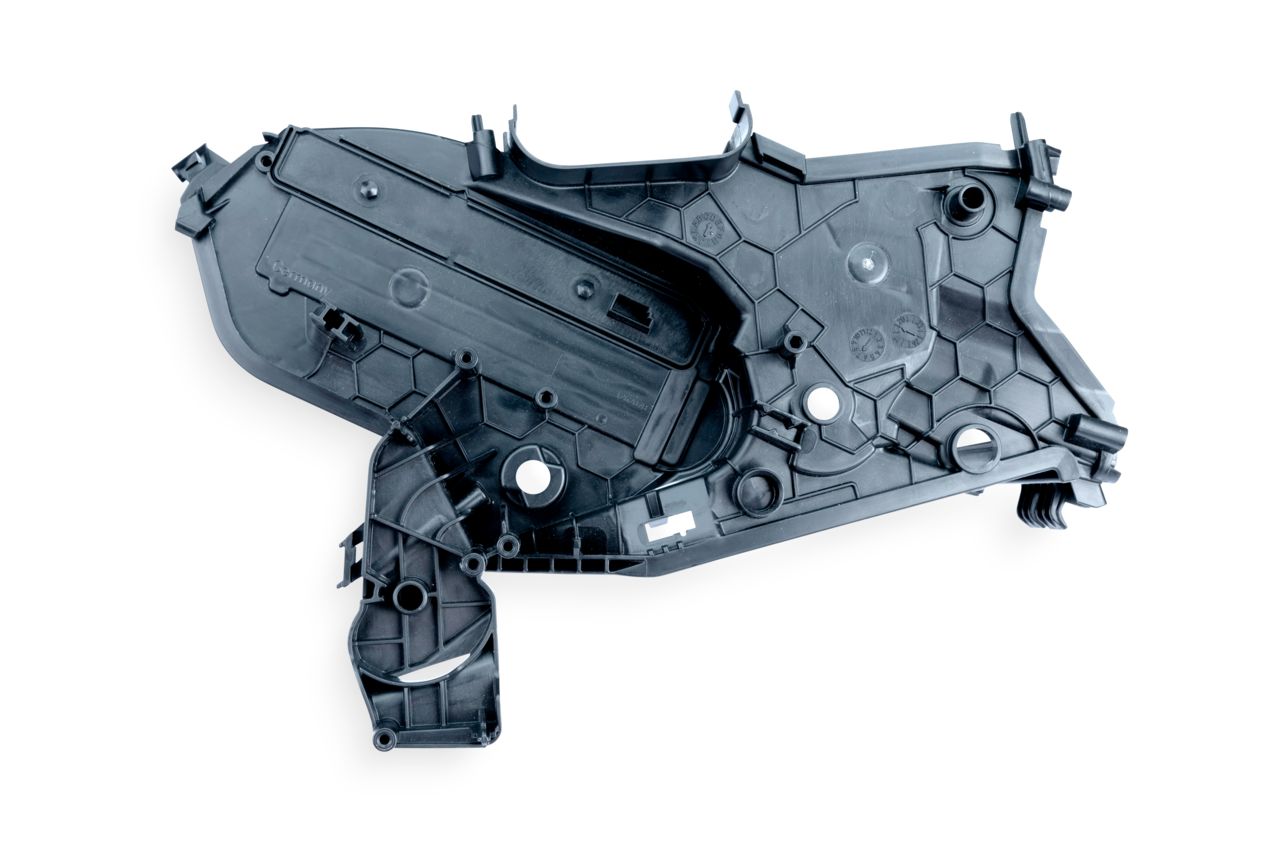

- Item: housing

- Material: PP+LGF

- Part weight: 318 g

- Wall thickness: 2 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 1 + 1-drop

- Item: front-end module

- Material: PP + LGF

- Part weight: 4500 g

- Wall thickness: 3 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 1-drop

- Item: display cover

- Material: PC/ABS + PC

- Part weight: ≈ 5 + 3 g

- Wall thickness: ≈ 1,5 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 4 + 4-drop

- Particularity: multi-component technology

Requirements

- Functionally integrated surfaces

- Highest design requirements

- Lightweight design

- Multi-component technology

Matching products

Consumer goods and household appliances

Consumer goods manufacturers have demanding customers – fast design changes and high volumes are required. With our hot runner systems we offer the basis for successful production. This results in components with perfect surface quality and an optimal price/performance ratio.

- Item: knife insert

- Material: PP

- Part weight: 170 g

- Wall thickness: ≈ 1,5 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 1 + 1-drop

- Particularity: stack mould

- Item: plug-in seals

- Part weight: ≈ 3 g

- Wall thickness: ≈ 1,5 mm

- Hot runner system: smartFILL RT

- Number of cavities: 16-drop

- Item: soap dispenser

- Material: PP

- Part weight: ≈ 3 g

- Wall thickness: ≈ 1,5 mm

- Hot runner system: smartFILL NZ

- Number of cavities: 16-drop

- Item: dummy / dummy box

- Material: PP

- Part weight: ≈ 2 g / ≈ 1 g

- Wall thickness: ≈ 2 mm / ≈ 1 mm

- Hot runner system: smartFILL NZ / RT

- Number of cavities: 16-drop

- Particularity: multi-component technology

Requirements

- High surface quality

- Attractive product designs

- Sustainable materials

- Family, multi-cavity and stack moulds

- Multi-component technology

Matching products

Empresa

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

Quick Links

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]