Contatto

Siamo a vostra disposizione da lunedì a venerdì dalle ore 8:00 alle ore 17:00. In questo link troverete le persone di contatto per la vostra regione.

Sede di Wolfurt

+43 5574 6706-0

Carrello acquisti {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Articoli Cambia carrello acquisti

Nota

| Foto | Articoli | Pz. | Prezzo singolo | Prezzo unitario | Prezzo unitario incluso lo sconto | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Clienti

- Costruzione stampi

- Stampi per tranciatura

- Costruzione macchine e dispositivi

- Progettisti

- Stampaggio ad iniezione

-

Prodotti

- Nuovi prodotti

- Portastampi

-

Basi portastampo

- La base portastampo standard SV

- Basi portastampo di precisione SP

- Base portastampo a due colonne con guida posteriore SH

- Base portastampo diagonale a due colonne SD

- Base portastampo centrale a due colonne SZ

- Tecnica modulare SM

- BASI PORTASTAMPO TRANCIA-PIEGATRICI SB

- Sistema di staffaggio H 3000

- Piastre P

- Barre N

- Piastre e barre

- Lavorazioni speciali

- Accessori E

- Tecnica del canale caldo

- Termoregolazione canale caldo

- Prodotti per l‘officina

- Azienda

- Carriera

- Servizio clienti

Siamo il vostro partner in ogni fase del progetto.

Le vostre idee incontrano le nostre soluzioni

La nostra tecnologia a canale caldo copre da oltre 60 anni i requisiti di utilizzo in termini di proprietà fisiche, materiali, integrazione funzionale, qualità delle superfici e forme complicate. Da noi troverete la soluzione ideale per il canale caldo.

Sistemi a canale caldo personalizzati

Sistemi a canale caldo standardizzati

Servizio clienti e supporto

Il nostro team vi fornirà un supporto completo, dalla fase di concezione e progettazione del design del sistema, fino alla messa in servizio e alla manutenzione. Riceverete un feedback entro 24 ore, in ogni fase del progetto. I nostri esperti tecnici vi supporteranno sia nell’ottimizzazione dei processi di stampaggio ad iniezione, sia nella lavorazione di materiali diversi, che nella progettazione dei vostri concetti di stampi.

Settori

Imballaggi

Che si tratti di un gran numero di chiusure o di svariate confezioni, offriamo all’industria dell’imballaggio le soluzioni a canale caldo ideali per progettare in modo efficiente i processi di produzione ed ottenere così la massima redditività del sistema. Vi supportiamo nella produzione di pezzi in materiale plastico funzionali, sostenibili e di qualità.

- Articolo: Cappuccio a ribalta

- Materiale: PP

- Peso particolare: ≈ 2 g

- Spessore della parete: ≈ 1 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 16

- Articolo: Tappi di chiusura

- Materiale: PP+TPE

- Peso particolare: ≈ 2 + 0,8 g

- Spessore della parete: ≈ 3 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 8 + 8

- Particolarità: Tecnologia multicomponente

- Articolo: Cappuccio

- Materiale: PP

- Peso particolare: ≈ 2 g

- Spessore della parete: ≈ 1,5 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 24

- Articolo: Cappuccio

- Materiale: PE LD

- Peso particolare: ≈ 2 g

- Spessore della parete: ≈ 1 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 24

- Articolo: Tappi in plastica

- Materiale: PP

- Peso particolare: ≈ 2 g

- Spessore della parete: ≈ 1,5 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 16

Requisiti

- Cambio colore rapido

- Brevi tempi di ciclo

- Elevata qualità superficiale

- Prodotti estetici

- Materiali sostenibili

Prodotti compatibili

Medicale

Stabilità dimensionale, precisione, riproducibilità, applicazioni in camera bianca – le nostre soluzioni a canale caldo garantiscono un’elevata affidabilità di processo e pezzi in materiale plastico perfetti, soprattutto per le applicazioni più complesse del settore medicale.

- Articolo: Catetere

- Materiale: PA12

- Peso particolare: 4 g

- Spessore della parete: 5 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 2

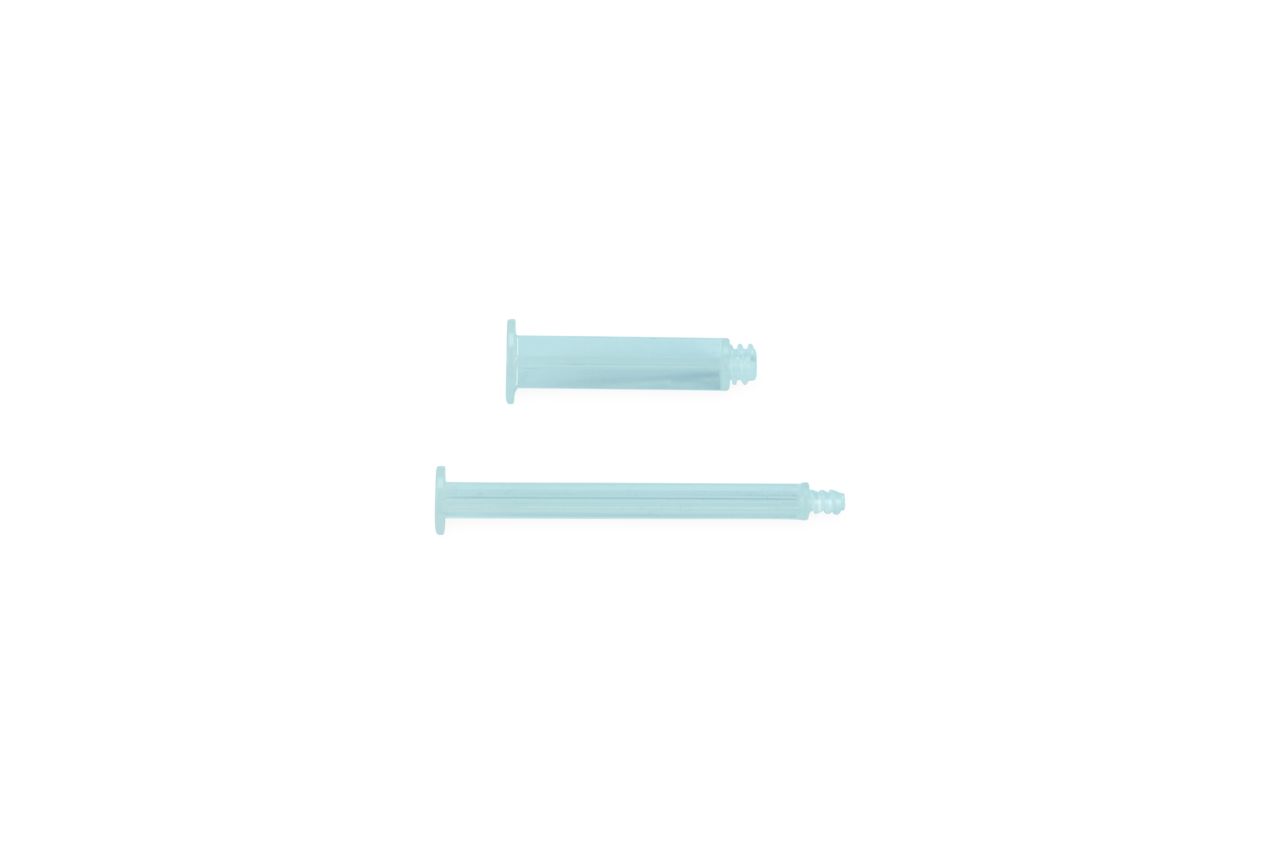

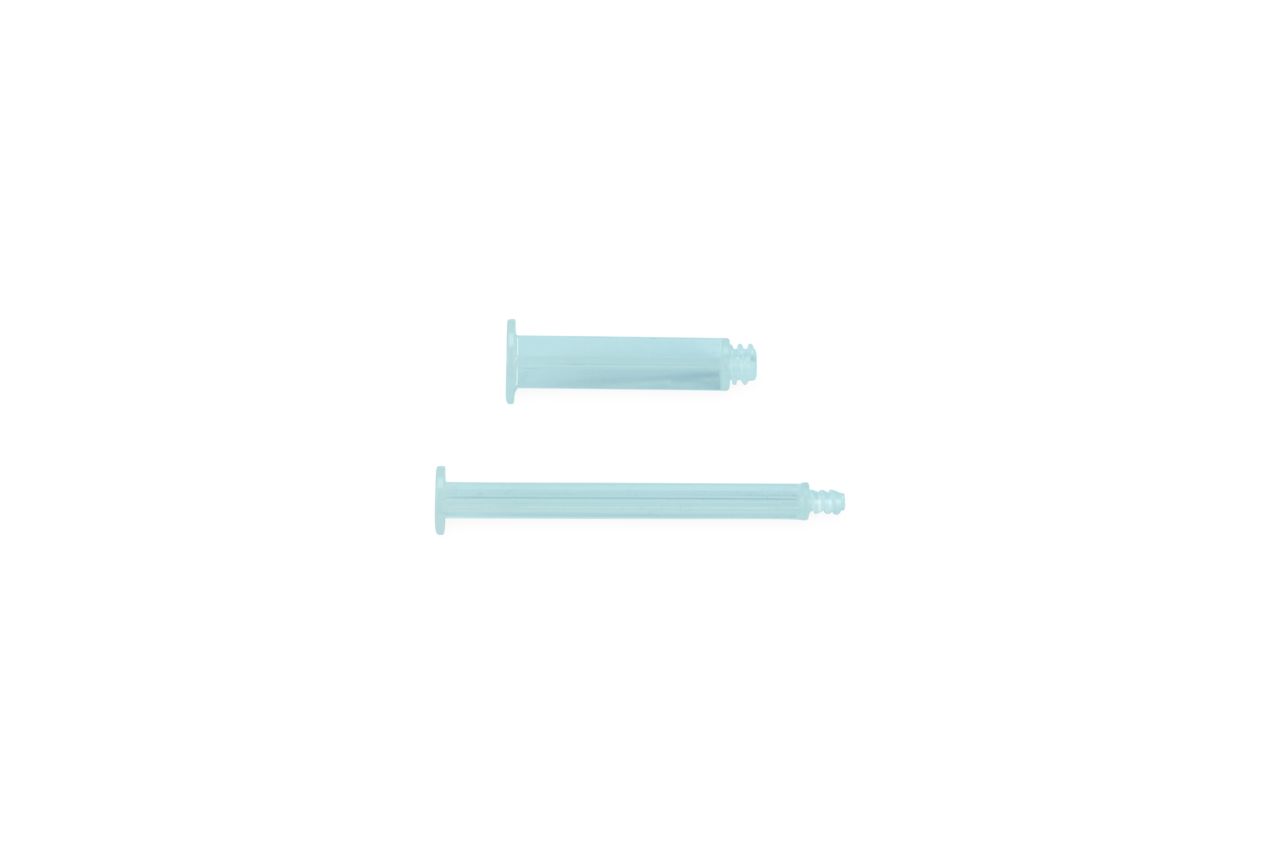

- Articolo: Pistone per siringa

- Materiale: PP

- Peso particolare: ≈ 1 g

- Spessore della parete: ≈ 1 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 24

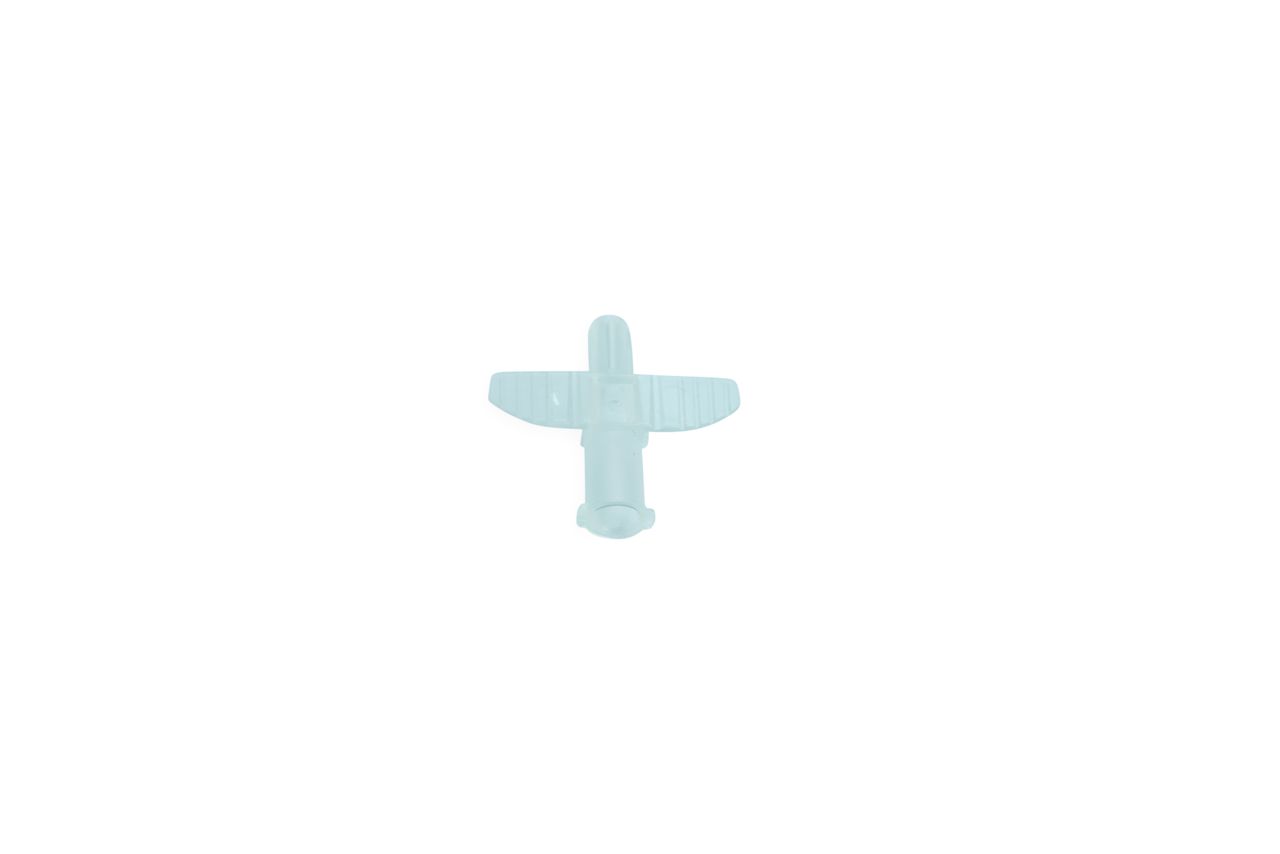

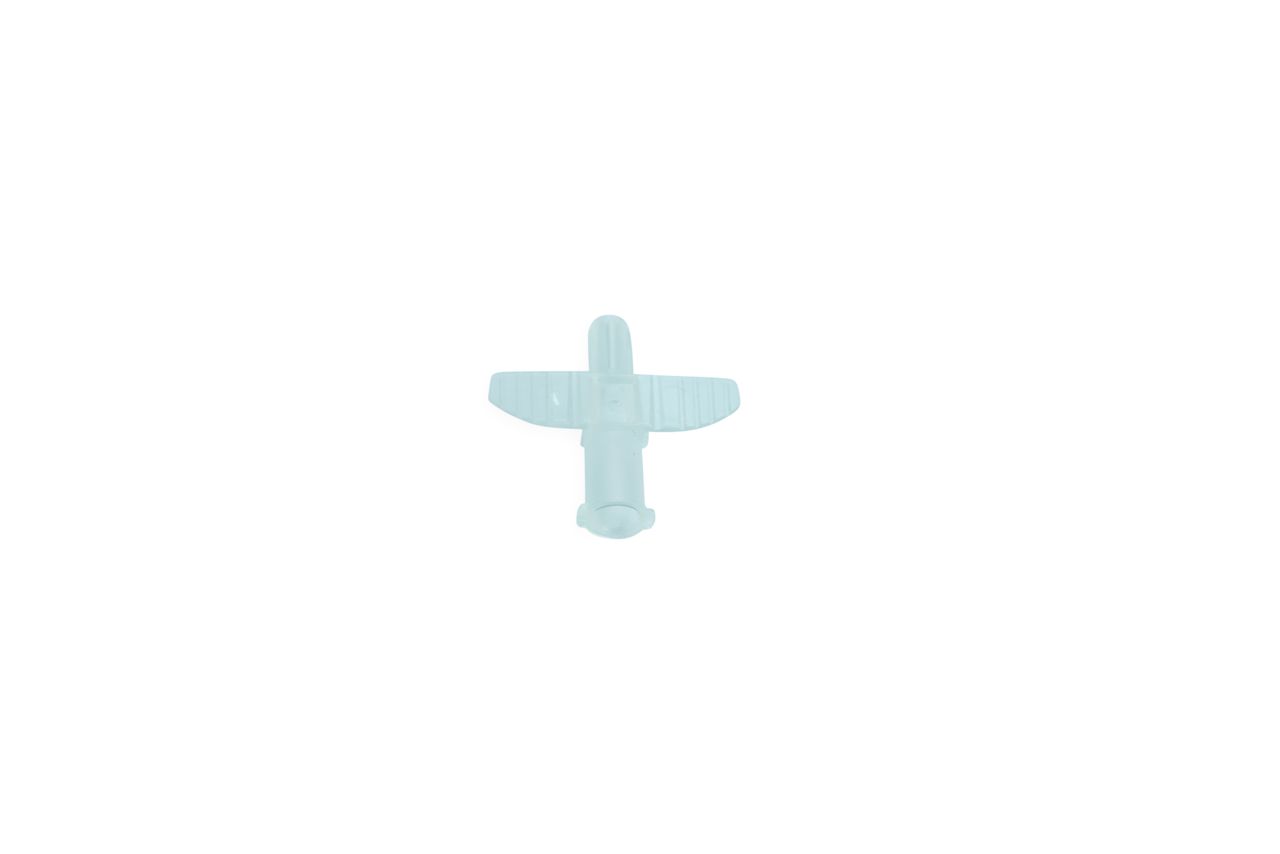

- Articolo: Bocchino per inalatore

- Materiale: PP

- Peso particolare: ≈ 2 g

- Spessore della parete: ≈ 1 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 8

- Articolo: Coperchio per dializzatore

- Materiale: PC

- Peso particolare: 3,2 g

- Spessore della parete: ≈ 1 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 16

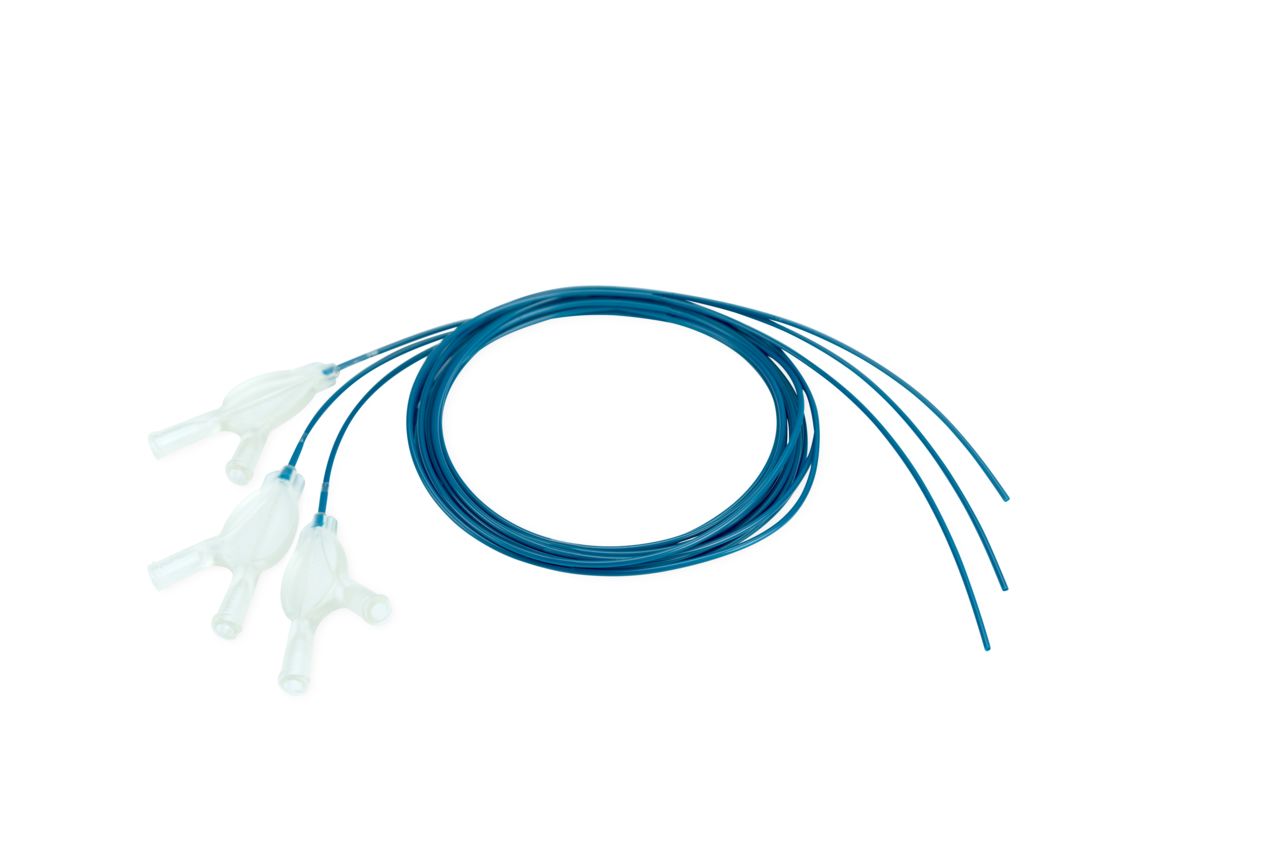

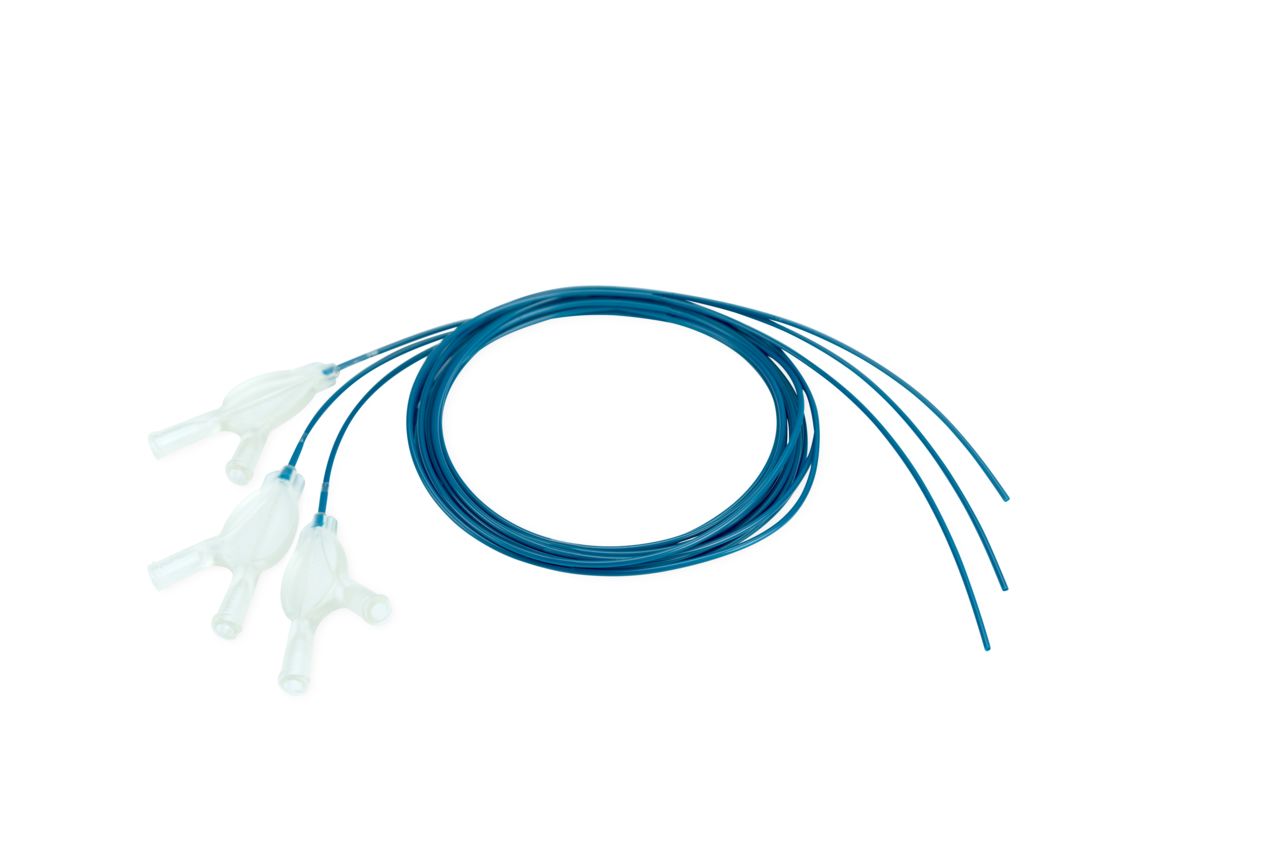

- Articolo: Cannula per flebo

- Materiale: PP

- Peso particolare: ≈ 1 g

- Spessore della parete: ≈ 1 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 24

Requisiti

- Precisione e stabilità dimensionale

- Biocompatibilità

- Sterilizzabilità

- Stabilità a lungo termine

- Punti di iniezione cosmetici

Prodotti compatibili

Trasporto

I pallet o le casse per il trasporto devono resistere a molte cose: sollecitazioni meccaniche, temperature fluttuanti o elevati raggi UV. Che si tratti di elevate grammature di iniezione, stampi sandwich o stampi familiari complessi, siamo lieti di offrirvi le nostre conoscenze accumulate nel settore dei sistemi a canale caldo.

- Articolo: Scatola pieghevole

- Materiale: PP

- Peso particolare: 1980 g

- Spessore della parete: 2,5 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 1 + 2 + 2

- Particolarità: Stampo familiare

- Articolo: Contenitori in plastica Eurobox

- Materiale: PP

- Peso particolare: 500–1900 g

- Spessore della parete: ≈ 2 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 2

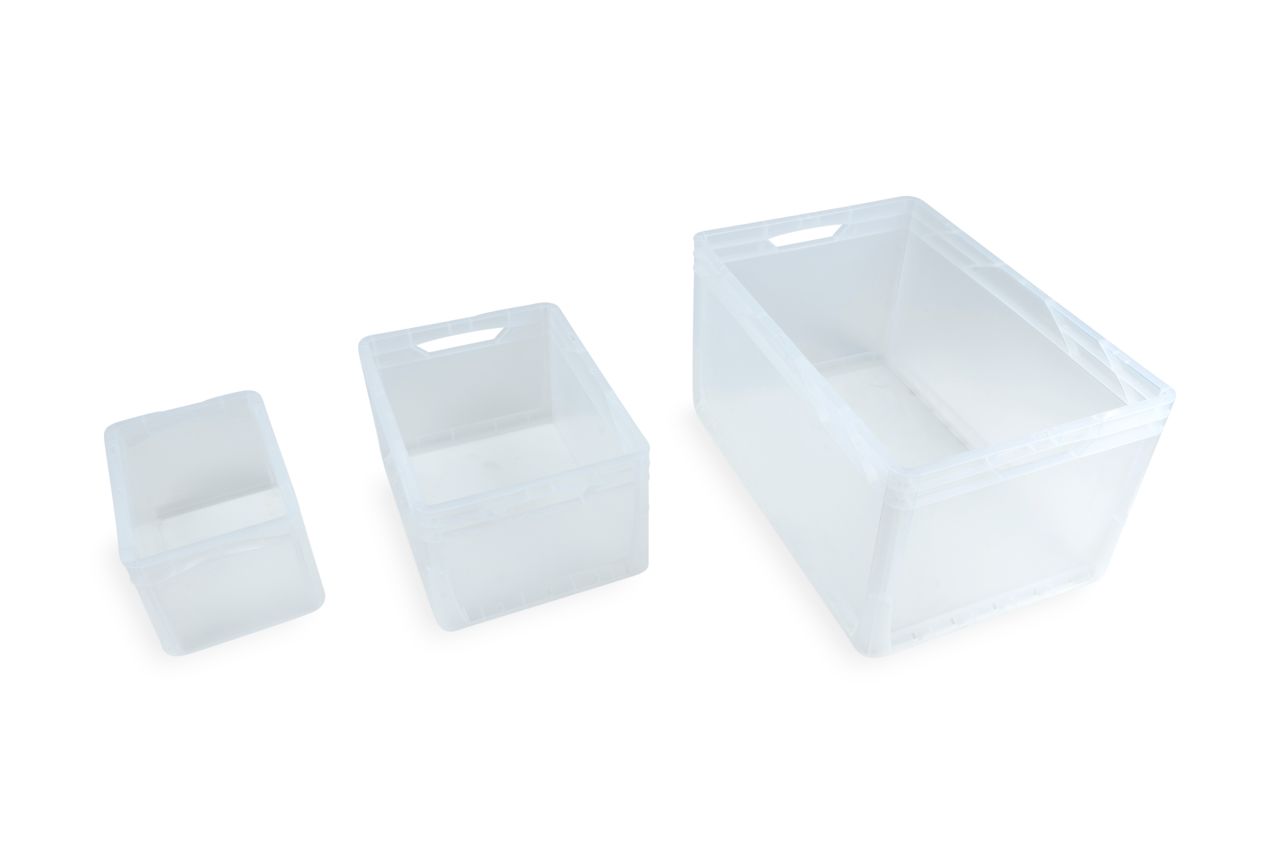

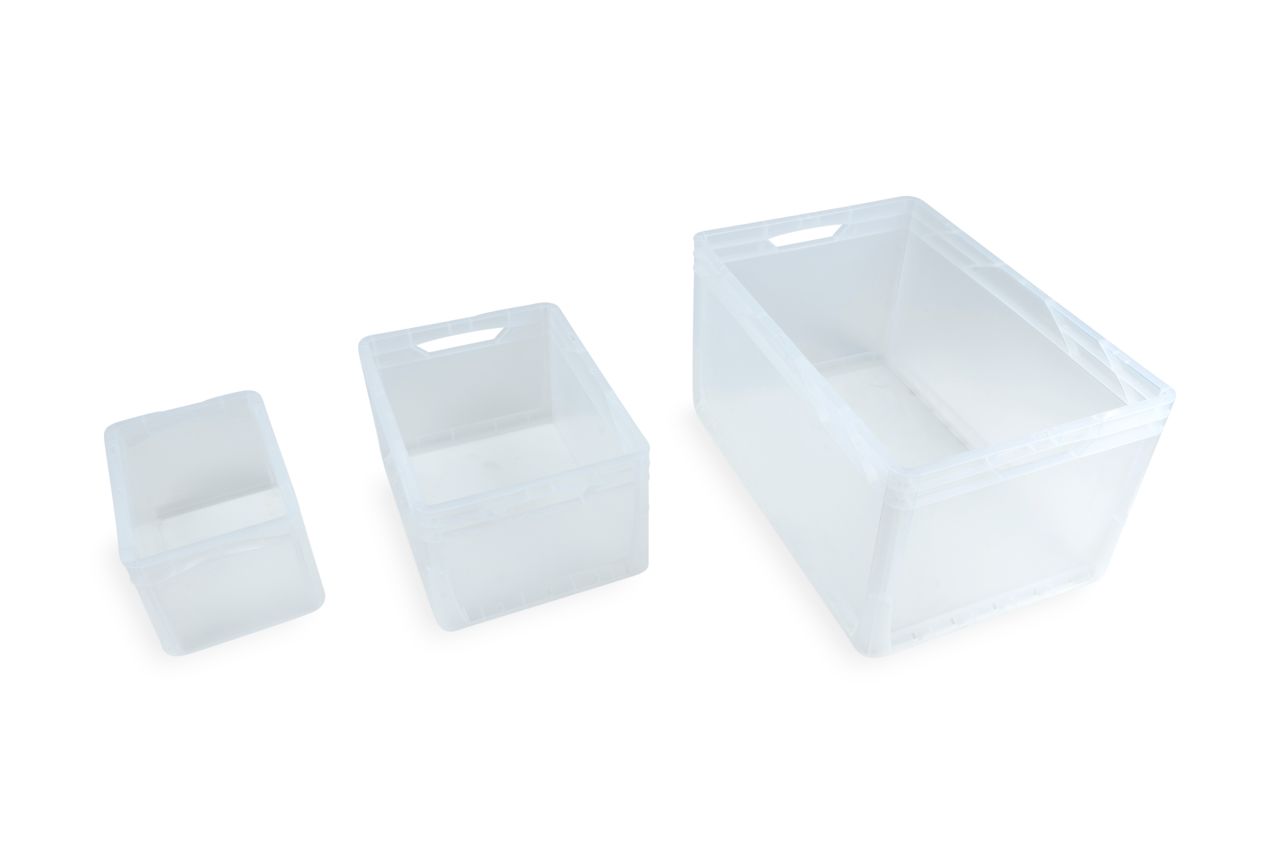

- Articolo: Scatola di smistamento

- Materiale: PP

- Peso particolare: 300–1500 g

- Spessore della parete: ≈ 2 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 2

- Articolo: Pallet

- Peso particolare: 15,000 g

- Spessore della parete: ≈ 10 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 1

Requisiti

- Geometrie complesse

- Elevate grammature di iniezione

- Capacità di carico meccanica

- Etichetta nello stampo

- Stampi sandwich e stampi familiari

Prodotti compatibili

Componenti tecnici

I componenti tecnici vengono montati in prodotti innovativi e richiedono un elevato grado di precisione. Utilizziamo principalmente tecnopolimeri e materie plastiche ad alta prestazione con e senza sostanze rinforzanti, per garantire un’elevata capacità di carico meccanica e una buona riproducibilità dei prodotti. In questo settore, vi offriamo sistemi ad otturazione per un’ottimale qualità dei manufatti plastici.

- Articolo: Scatola a muro e coperchio per scatola

- Materiale: PS V0

- Peso particolare: 1425 g + 610 g

- Spessore della parete: ≈ 2 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 1 per ciascuna

- Articolo: Scatole elettriche da parete

- Materiale: POM-H

- Peso particolare: ≈ 1–10 g

- Spessore della parete: ≈ 1–2 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 16

- Articolo: Spina

- Materiale: LCP

- Peso particolare: ≈ 2 g

- Spessore della parete: ≈ 0,8 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 8

- Articolo: Alloggiamento

- Materiale: POM-C

- Peso particolare: 7 g

- Spessore della parete: ≈ 1,5 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 8

- Articolo: Coperchio

- Materiale: PC

- Peso particolare: 425 g

- Spessore della parete: ≈ 2 mm

- Sistema a canale caldo: smartFILL EH 4050

- Numro di cavità: 1

Requisiti

- Materie plastiche ad alta prestazione

- Sostanze riempitive e rinforzanti

- Funzioni complesse

- Ottime proprietà meccaniche

- Elevata riproducibilità & lunga durata di vita

Prodotti compatibili

Settore automobilistico

Siamo il vostro partner competente per i più svariati requisiti dell’industria automobilistica. Questi includono applicazioni di costruzioni leggere, componenti interni visivamente sofisticati e pezzi multicomponente speciali nel settore dell’acustica dei veicoli. Indipendentemente dalle vostre esigenze, siamo in grado di sviluppare la soluzione a canale caldo per il vostro progetto affidandoci alla nostra pluriennale esperienza nel settore.

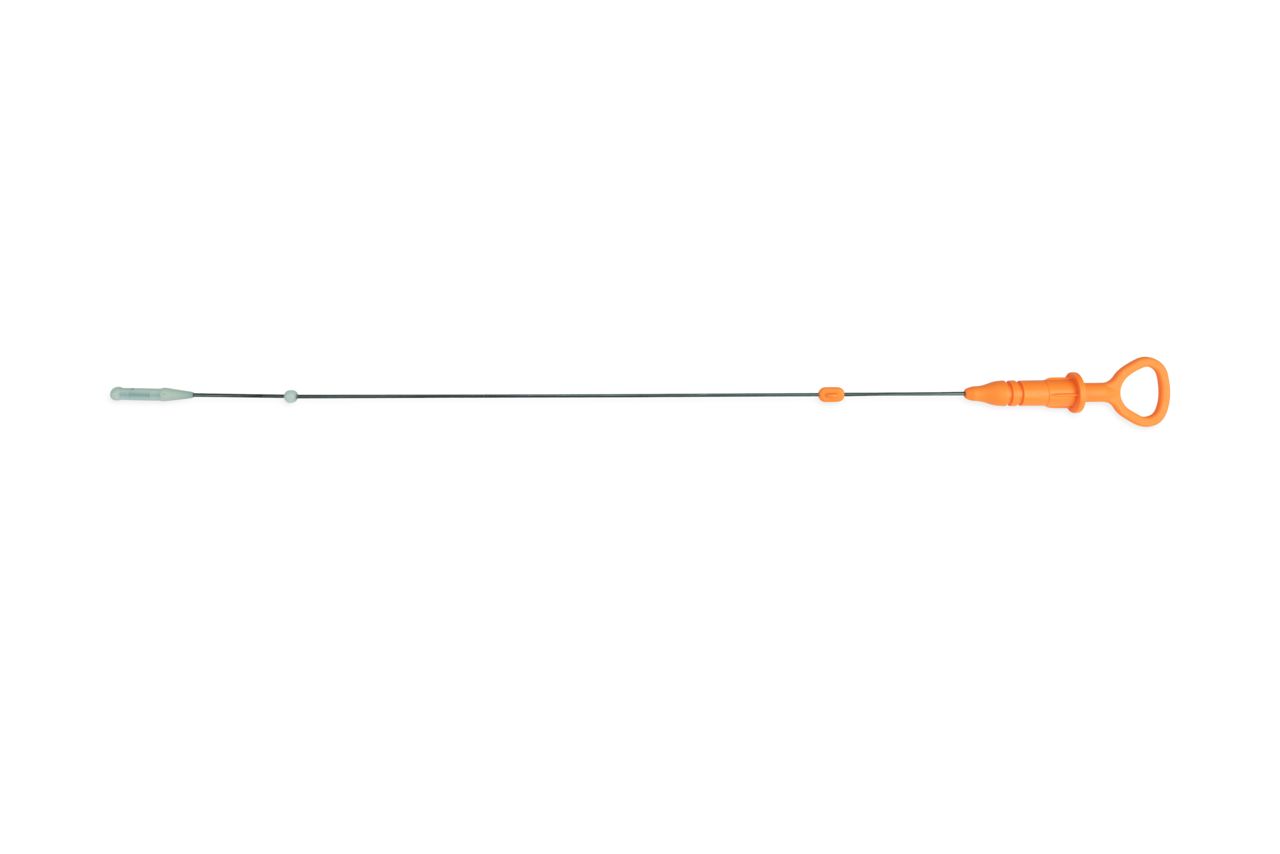

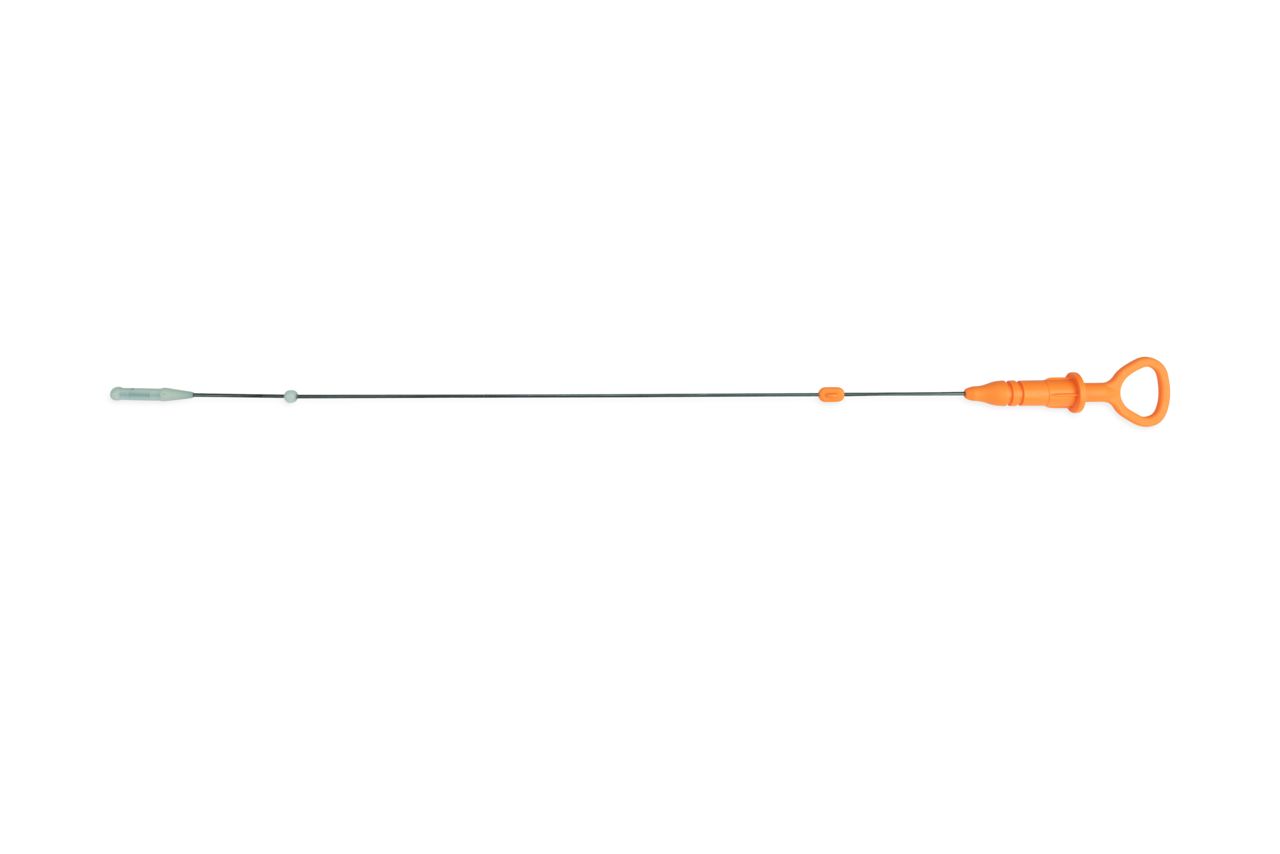

- Articolo: Asta di livello dell’olio

- Materiale: PA6.6

- Peso particolare: ≈ 6 g + 2 g

- Spessore della parete: ≈ 2–6 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 4 + 4

- Particolarità: Incapsulamento metallico

- Articolo: Coperchio del motore

- Materiale: PA6.6 GF35

- Peso particolare: 650 g

- Spessore della parete: ≈ 3,5 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 4

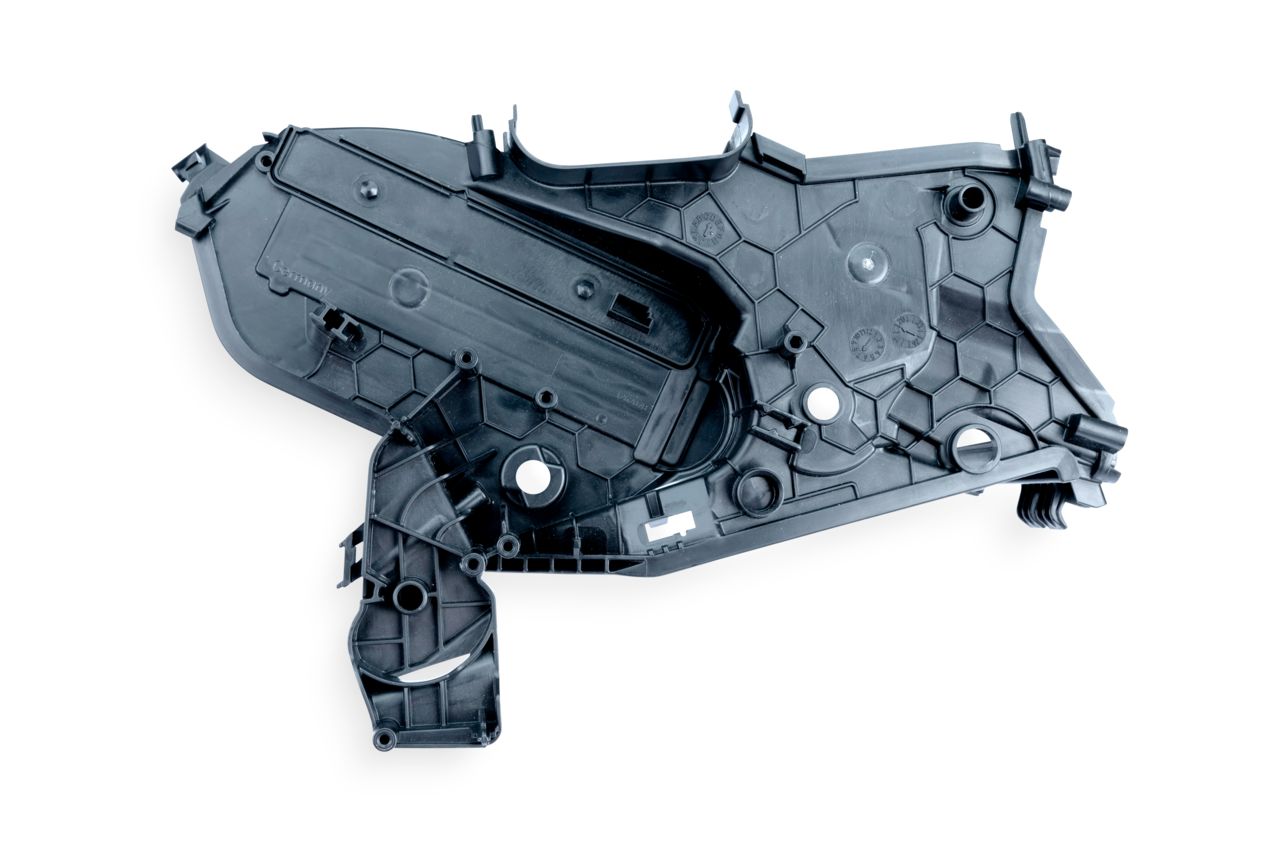

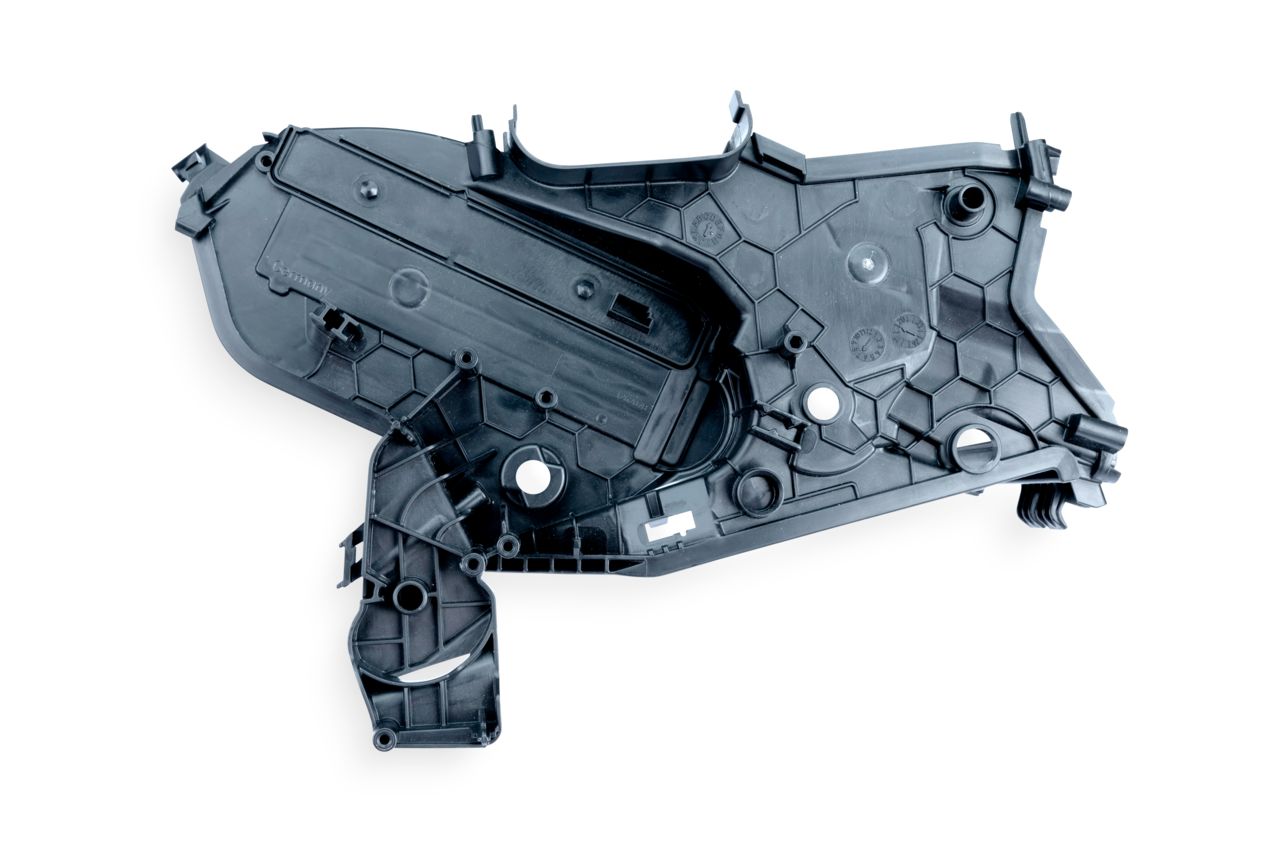

- Articolo: Alloggiamento

- Materiale: PP+LGF

- Peso particolare: 318 g

- Spessore della parete: 2 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 1 + 1

- Articolo: Frontend

- Materiale: PP + LGF

- Peso particolare: 4500 g

- Spessore della parete: 3 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 1

- Articolo: Coperchio del display

- Materiale: PC/ABS + PC

- Peso particolare: ≈ 5 + 3 g

- Spessore della parete: ≈ 1,5 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 4 + 4

- Particolarità: Tecnologia multicomponente

Requisiti

- Superfici integrate funzionalmente

- Requisiti di progettazione più elevati

- Costruzione leggera

- Tecnologia multicomponente

Prodotti compatibili

Beni di consumo ed elettrodomestici

I produttori di beni di consumo hanno clienti esigenti – vengono richieste modifiche rapide al design ed elevati numeri di pezzi. Con i nostri sistemi a canale caldo, poniamo le basi per una produzione di successo. Il risultato sono componenti con un’elevata qualità superficiale ed un ottimo rapporto qualità/prezzo.

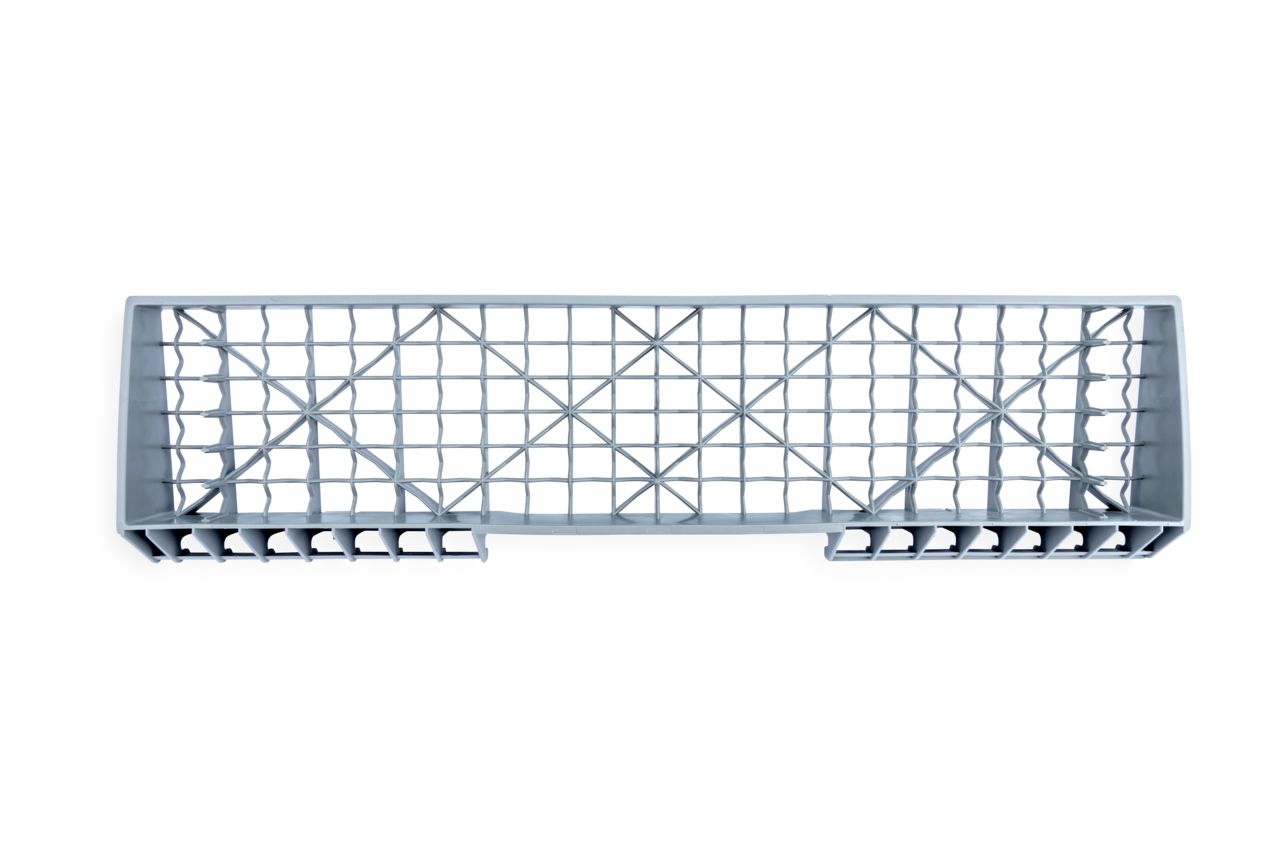

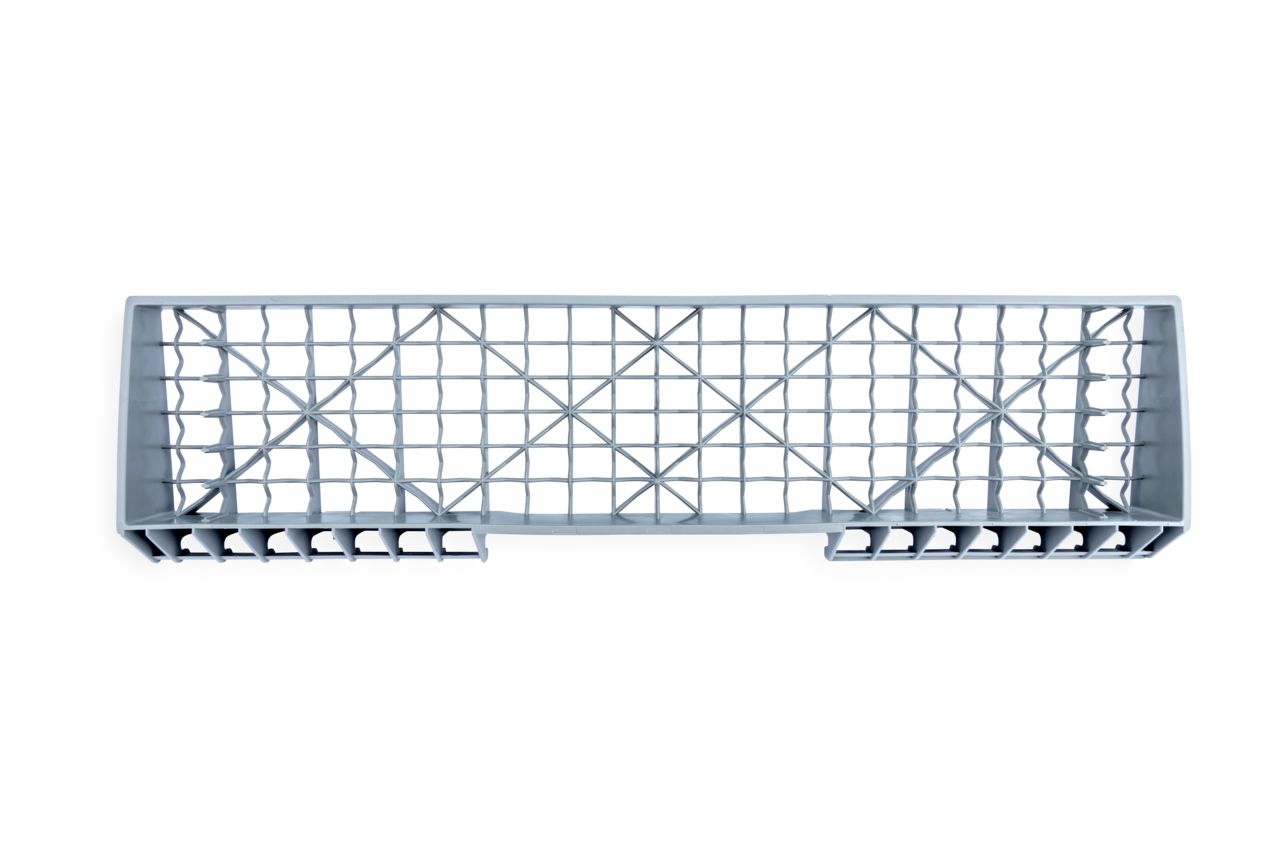

- Articolo: Portaposate

- Materiale: PP

- Peso particolare: 170 g

- Spessore della parete: ≈ 1,5 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 1 + 1

- Particolarità: Stampo sandwich

- Articolo: Guarnizioni ad incastro

- Peso particolare: ≈ 3 g

- Spessore della parete: ≈ 1,5 mm

- Sistema a canale caldo: smartFILL RT

- Numro di cavità: 16

- Articolo: Dosatore di sapone

- Materiale: PP

- Peso particolare: ≈ 3 g

- Spessore della parete: ≈ 1,5 mm

- Sistema a canale caldo: smartFILL NZ

- Numro di cavità: 16

- Articolo: Ciuccio / scatola per ciuccio

- Materiale: PP

- Peso particolare: ≈ 2 g / ≈ 1 g

- Spessore della parete: ≈ 2 mm / ≈ 1 mm

- Sistema a canale caldo: smartFILL NZ / RT

- Numro di cavità: 16

- Particolarità: Tecnologia multicomponente

Requisiti

- Elevata qualità di superficie

- Prodotti estetici

- Materiali sostenibili

- Stampi familiari, stampi multicavità e stampi sandwich

- Tecnologia multicomponente

Prodotti compatibili

Azienda

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]