The surface quality achieved with bending operations is often rather poor due to the sliding friction between the punch and the metal strip. As a result additional processing steps must be carried out leading to higher costs and longer lead times.

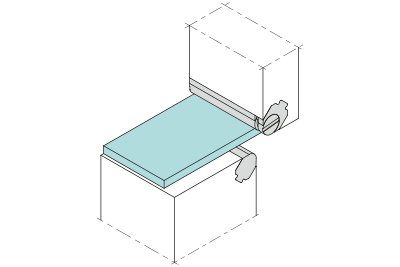

With the E 5690 bending unit, rolling friction occurs between the bending unit and the sheet metal strip which leads to significantly better surface quality in the bending area and high-quality forming results even with soft, coated and lacquered materials. An additional advantage is the freely rotatable bearing roller which enables an unlimited stroke.

The bending unit is available from stock in diameters 3–10 mm and in lengths 25–100 mm. The length can be easily shortened to the desired size by means of wire EDM. The perfect match for the bending unit is the E 5692 bending insert.

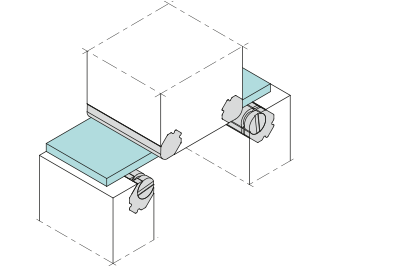

The bending unit E 5690 in action

By using the bending unit, follow-up work (polishing) is no longer necessary.

Bending unit E 5690

- Highest surface quality in the bending area due to rolling friction reduces follow-up work and allows for higher stroke speeds

- High-quality forming of soft, coated and lacquered materials

- Repair of worn bending punches possible

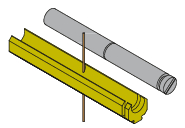

Bending insert E 5692

- Installation of the hardened bending insert makes the use of more economical materials possible

- Suitable for testing new coatings as only the bending insert must be coated

- Low-cost repairs as only the bending insert has to be replaced

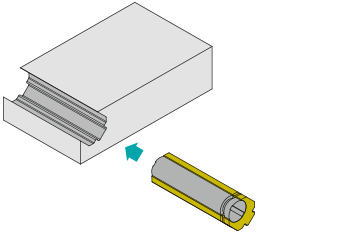

Assembly

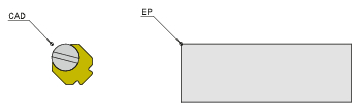

CAD ZERO POINT

CAD: CAD zero point

EP: corner point

POSITION BENDING UNIT IN PUNCH

Place the CAD zero point of the bending unit on the corner point.

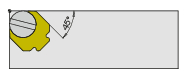

WIRE EDM CONTOUR

EDM contour in the punch (G7 tolerance).

SHORTEN BENDING UNIT

Cut bending unit to required length by wire EDM (roller and holder separately).

Mount retaining clip

GLUE BENDING UNIT

Glue bending unit with VBA 2M43.

Make sure that the retaining clip is completely surrounded by the punch, otherwise it may get lost.

FAQs

How do I know what size to use?

Select the size that is closest to the radius of the original die. Next, select the length of the bending unit or bending insert and cut to length as needed. Make sure that the retaining clip remains retained in the bending unit.

Does the roller need to be lubricated?

Lubrication is optional. Experience shows that after converting sliding friction to rolling friction, the use of lubrication is the next best step to further reducing friction. However, the time and work required for lubrication and the environmental aspects must be considered.

How can I repair a damaged die with these inserts?

Most often, damage occurs in the bending area of the die. Since this is the area of the die that can be replaced by the bending unit and bending insert, it doesn't matter if it is new or worn when it is installed.

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]