Milling graphite

Graphite is not plastically deformable and thus not machinable in the true sense of the word. In the machining process, individual grains are knocked out of the composite in a controlled manner. This leads to an abrasive attack on the cutting surface of the tool and requires a relatively high wear resistance of the cutting material. This effect occurs during dry machining and can be reduced with high cutting speeds. Especially the wear of diamond-coated or PCD tools decreases with increased cutting speed and at a higher feed per tooth, which leads to optimal machining results. At the same time, the increased machining speed further optimises the work result.

Advantages

- Reduced costs due to low wear

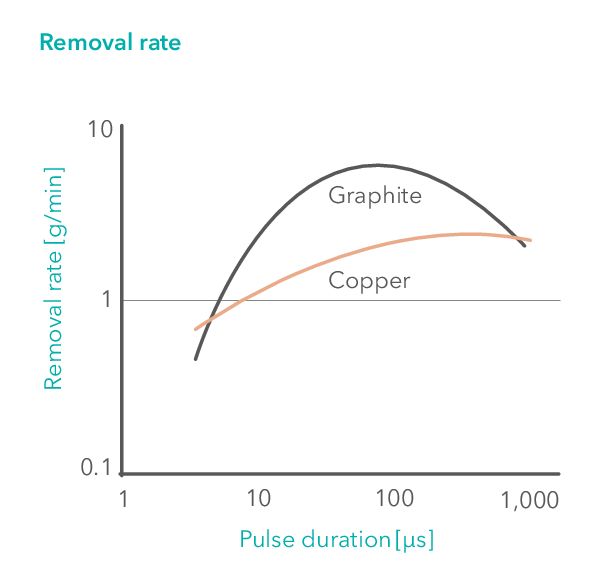

- Increased productivity due to high removal rates

- Filigree geometries possible

- No rework necessary

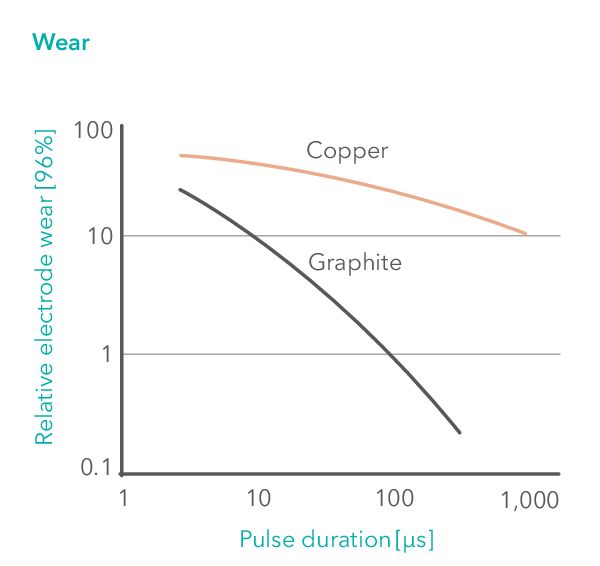

EDM with graphite

Graphite electrodes allow significant time and cost savings. Already during the design phase, different mould elements can be combined into one electrode in order to fully exploit the possibilities of modern and powerful EDM machines. The density is lower than that of copper by a factor of 4. This means that even large electrodes can be handled without any problems and with extreme precision.

Advantages

- Reduced costs due to long service life

- Precise EDM results

- Increased productivity

- Use of large electrodes possible

Meusburger graphite grades

We recommend using the appropriate graphite grade for the intended application:

Q70

- For surfaces from VDI 27 (2.2 μmRa) to VDI 24 (1.6 μmRa) depending on machine technology

- Low electrode wear

- Good surface

- Fast eroding process

Q60

- For surfaces of VDI 22 (1.26 μmRa)

- Ideal for high-quality finishing work

- For highly detailed shapes

- Good surface finish with good material removal rate

Q40

- For surfaces of VDI 20 (1.0 μmRa)

- Complicated electrodes with fine contours

- Low electrode wear with good removal rate

- For very demanding surface finishes

Q70 | Q60 | Q40 | |

|---|---|---|---|

| Average grain size: | 7 µm | 6 µm | 4 µm |

| Attainable surface finish | VDI 27 (2.2 µmRa) – VDI 24 (1.6 µmRa) | VDI 22 (1.26 µmRa) | VDI 20 (1.0 µmRa) |

| Density | 1.83 g/cm³ | 1.86 g/cm³ | 1.82 g/cm³ |

| Electrical resistance | 12.5 µΩ/m | 12 µΩ/m | 16.5 µΩ/m |

| Bending strength | 54 N/mm² | 65 N/mm² | 66 N/mm² |

| Hardness | 62 Shore | 60 Shore | 72 Shore |

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]