Copper electrodes

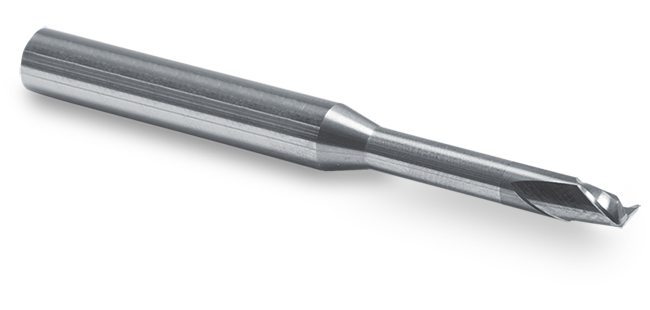

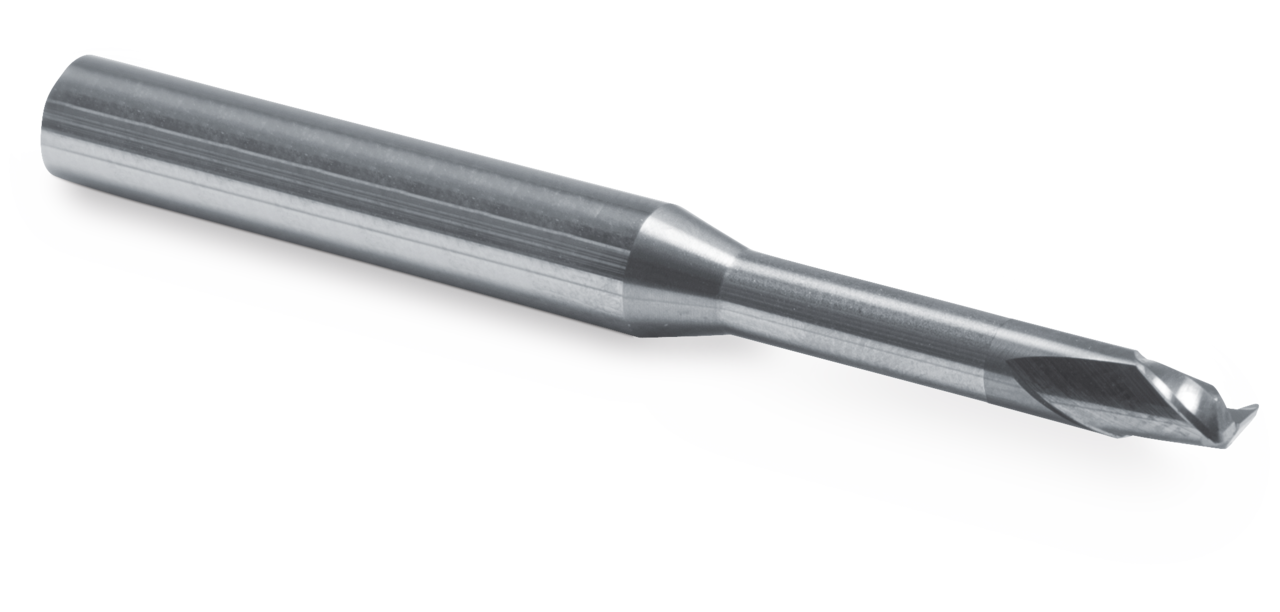

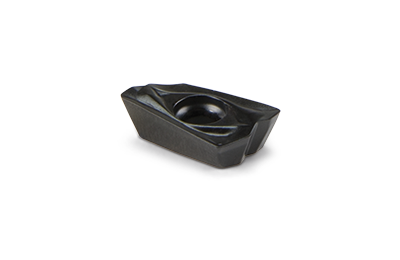

Due to the thermal sensitivity of copper materials, using the cutting tools incorrectly can cause warping and built-up edges on the tool. To avoid this, milling cutters with a specially adapted geometry are needed. Sharp cutting edges also ensure controlled chip formation and thus optimum results.

Challenge during machining:

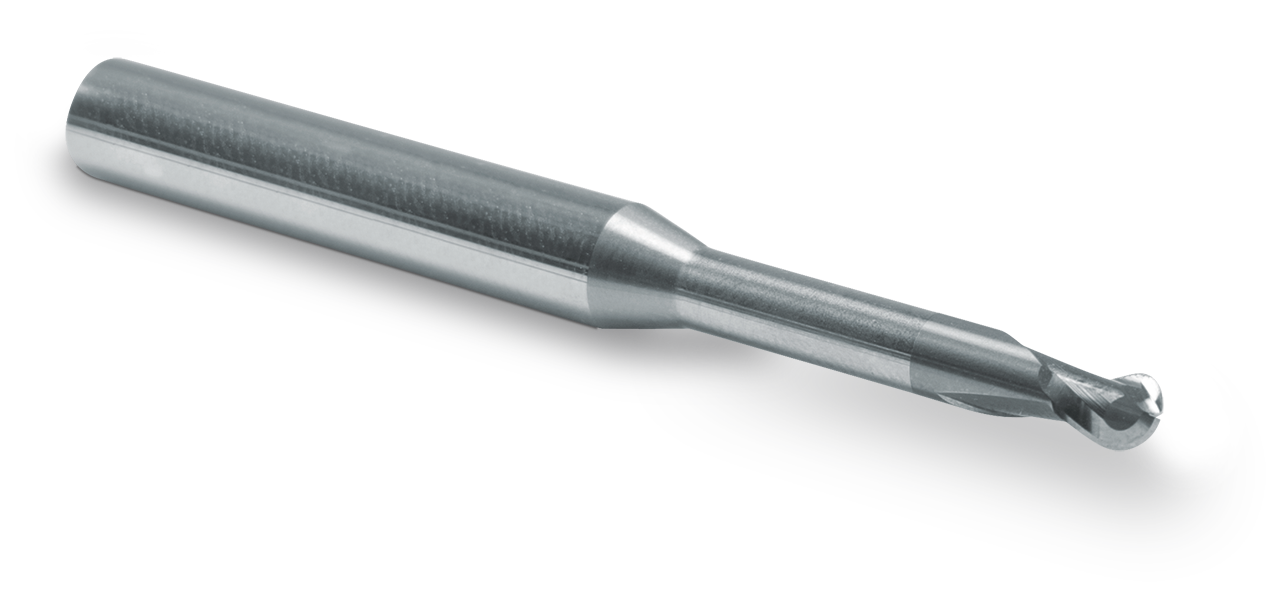

- Milling of complex and filigree contours

- Small radii and deep cross pieces

- Precision and surface quality at the highest level

Copper – Special requirements for cutting tools

Precise cutting tools are essential for perfect results when machining copper materials. Diameter, radius, shank and concentricity must be ground exactly to µ accuracy.

Our recommendation

Our practical tip for calculating cutting values

With our cutting data calculator, you can get the right cutting values in no time at all. What's more, we provide you with valuable information and tips for perfect use of the tool.

Aluminium materials

Depending on the requirements, different aluminium alloys are needed. When machining soft aluminium alloys, a number of points must be taken into account in order to obtain optimum results.

Challenge during machining:

- Different aluminium alloys are suitable to different extents for machining.

- Soft aluminium alloys tend to stick together and form built-up edges

- Ensure sufficient cooling during machining

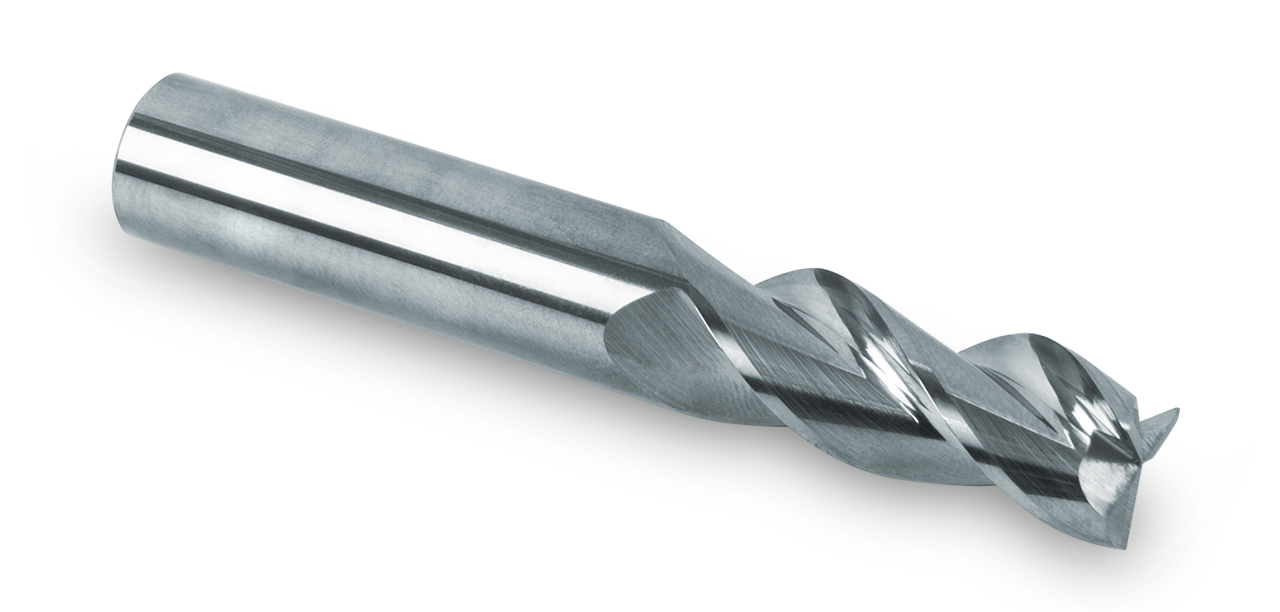

Aluminium materials – Special requirements for cutting tools

Our recommendation

Aluminium materials in the Meusburger product range

3.3547 Aluminium alloy

- Non-hardenable, homogenised, annealed aluminium alloy with particularly good machining and welding properties

- Excellent dimensional stability; ideally suited for anodising, hard chrome plating and chemical nickel plating

- High corrosion resistance

Designation according to DIN: AlMg4,5Mn / EN AW - 5083

3.4365 Aluminium zinc alloy

- Hardened, high strength aluminium-zinc alloy with good properties for grain etching

- Good machinability, EDM properties and polishability

Designation according to DIN: AlZnMgCu 1.5 / EN AW - 7075

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]