Kontakt

Vi står til rådighed mandag til fredag fra kl. 8:00 til kl. 17:00. Via dette link kan du finde din kontaktperson for dit område.

Central Wolfurt

+43 5574 6706-0

Kurv {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Produkt Skift indkøbskurv

Bemærkning

| Billede | Produkt | Stk. | Enkeltpris | Samlet pris | Samlet pris inkl. rabat | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Kunder

- Mould making

- Die making

- Maskin- og Fixtur konstruktion

- Konstruktoerer

- Sprøjtestøbere

- Produkter

- Firma

- Job opportunities

- Service

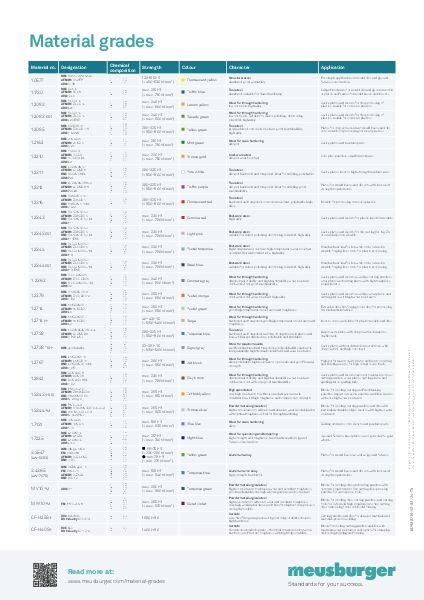

Vores udvalgte sortiment tilbyder det passende materiale til næsten alle anvendelser.

1.2738 Tool steel

Designation

| DIN: | 40 CrMnNiMo 8-6-4 |

| AFNOR: | 40 CMND 8 |

| UNI: | - |

| AISI: | ≈ P20 + Ni |

Chemical composition:

| C | 0.40 |

| Mn | 1.50 |

| Cr | 1.90 |

| Mo | 0.20 |

| Ni | 1.10 |

| Si | 0.30 |

Strength:

280 - 325 HB

(≈ 950 - 1100 N/mm²)

Thermal conductivity at 100 °C:

33.5 W/m K

Character:

low-sulphur tool steel, supplied in pre-toughened condition; due to its nickel content, it features uniform strength even with maximum plate dimensions

Application:

large cavity plates with deep cavities for items such as bumpers or dashboards, moulding frames

Treatment by

highly suitable:

Polishing, EDM, nitriding, etching

suitable:

Hard chrome

Heat treatment:

already pre-toughened; usually no heat treatment required

Soft annealing:

710 to 740 °C for about 2 to 5 hours; slow controlled cooling of 10 to 20 °C per hour to about 600 °C further cooling in air, max. 220 HB

Hardening:

840 to 870 °C

15 to 30 minutes keeping curing temperature

quenching in oil/hot bath/air 180 bis 220 °C

obtainable hardness: 53 HRC

Tempering:

slow heating to tempering temperature immediately after hardening; minimum time in furnace: 1 hour per 20 mm part thickness; tempering twice is recommended

Annealing graph:

Available in the web shop as:

Data sheet 1.2738

Firma

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2023 Meusburger

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

P-Standard plates

P-Standard plates

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]