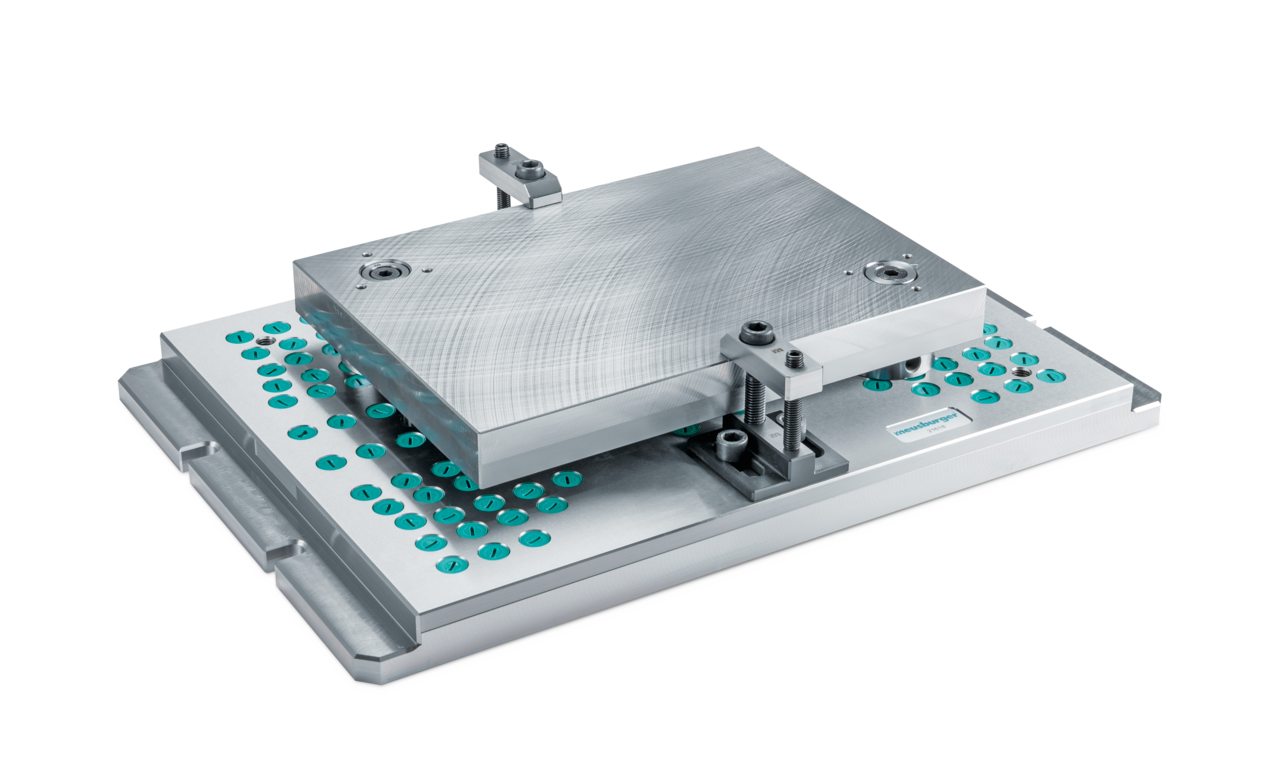

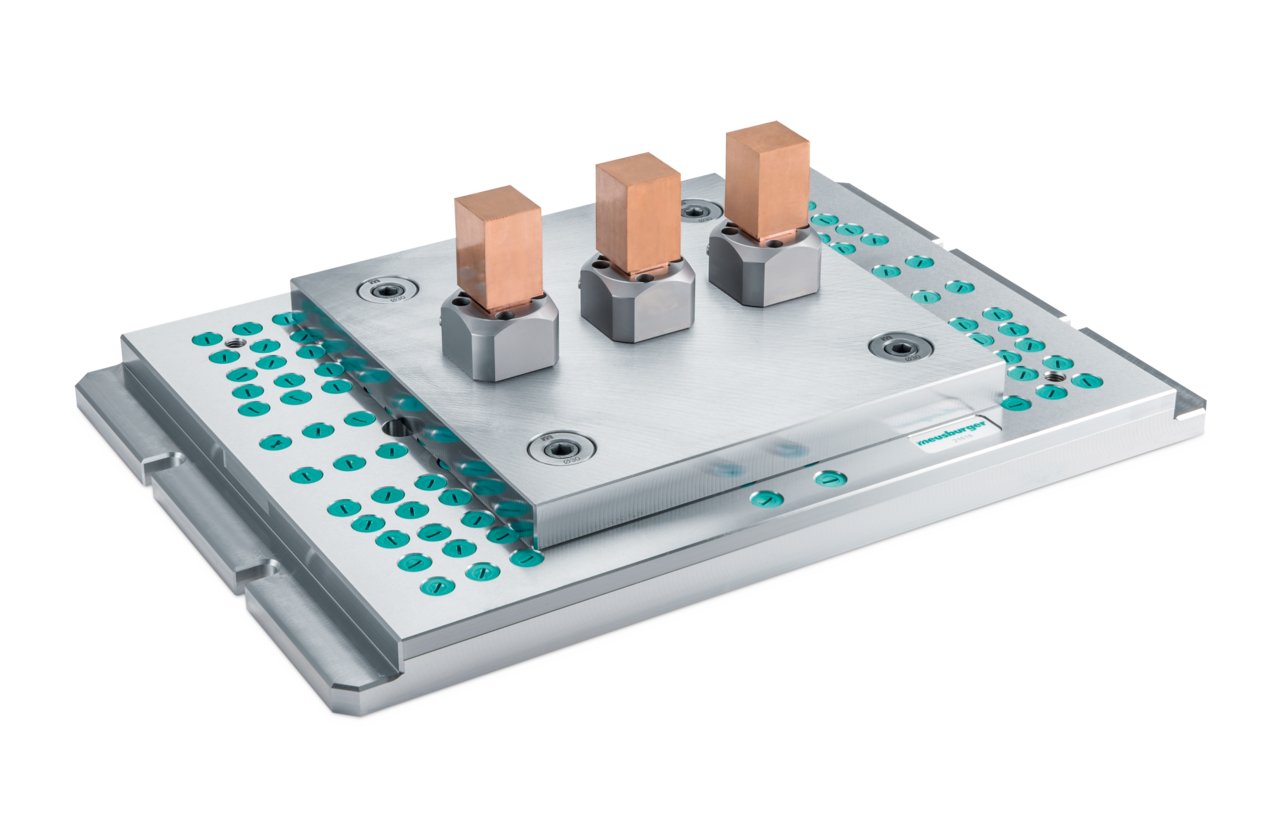

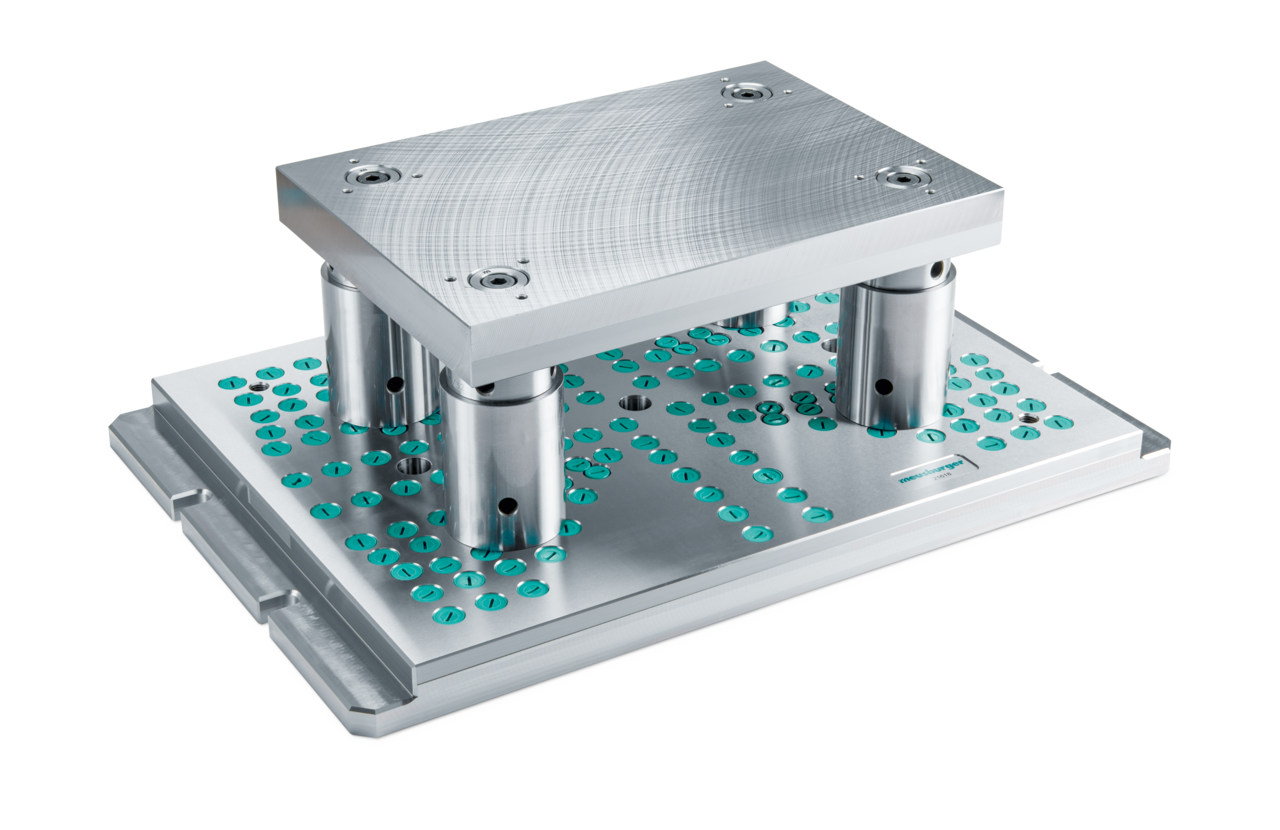

H 3000 FOR DIE MAKING - FAST AND PRECISE CLAMPING WITH REPEATABLE ACCURACY

The tried, trusted and advanced clamping system from Meusburger is now also available for die making. With the H 3000 you will not only work quickly and efficiently but also with absolute precision and repeatability. The plates are aligned and clamped where it is important for the die set function, i.e. in the guide holes.

YOU TOO CAN PROFIT FROM THE ADVANTAGES OF THE H 3000

- Significant reduction of set-up times by precise clamping in the μ range

- Increased quality of the parts through an exact and dimensionally perfect stamping die

- Simplified programming by clamping without interfering contours

Rely on Meusburger's many years of know-how in the area of clamping systems.

WITH OVER 2,000 H 1000 CLAMPING SYSTEMS SOLD IN MOULD MAKING, we are the market leader.

H 3000 WIZARD - FOR SIMPLIFIED CONFIGURATION

With our H 3000 Wizard you can quickly and easily configure your personal H 3000 Clamping system. First select the desired plate size and then easily assemble the clamping options for S-Plates and NP-Precision bars in the diameters you need. The fully automatic calculation of required clamping elements ensures that our clamping system is supplied completely. Optionally, additional packets for horizontal machining or pallets for clamping vices, electrode holders etc. can be added.

HOW YOU BENEFIT - AT A GLANCE:

- Easy and quick configuration of the H 3000 clamping system

- 2 different plate sizes offering various clamping options for die set plates and precision bars

- Fully automatic calculation of required clamping elements

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]