Nitrided ejector pin - oxidation coated from 1.2343

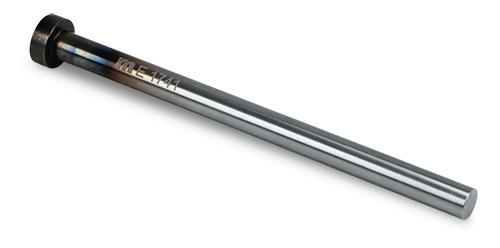

EJECTOR PINS FROM HSS 1.3343

Core pins from hot-work steel 1.2343

OVERVIEW OF EJECTOR AND CORE PINS FOR DIE CASTING

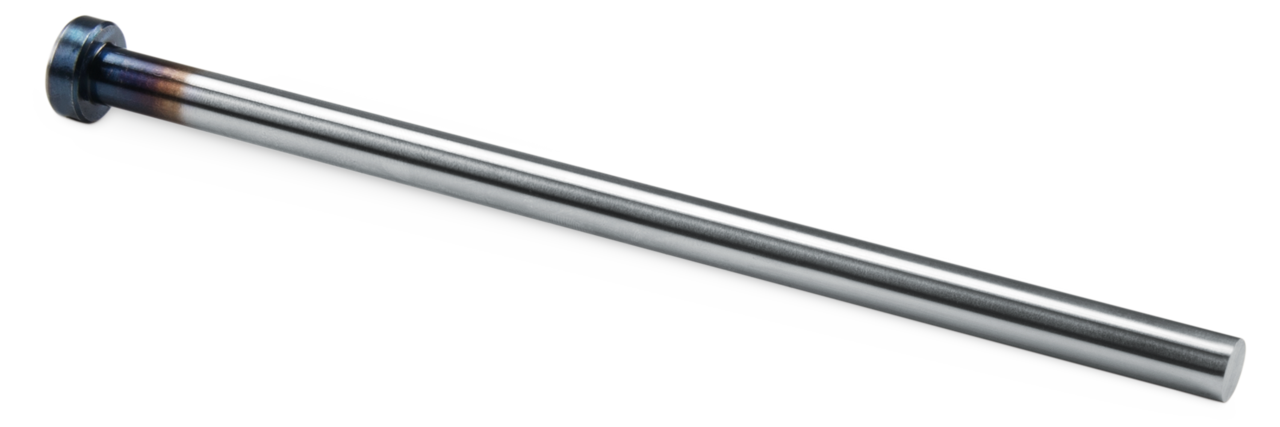

E 1740

- Material: 1.2343

- Heat treatment: nitrided - oxidation coated

- Shape: round

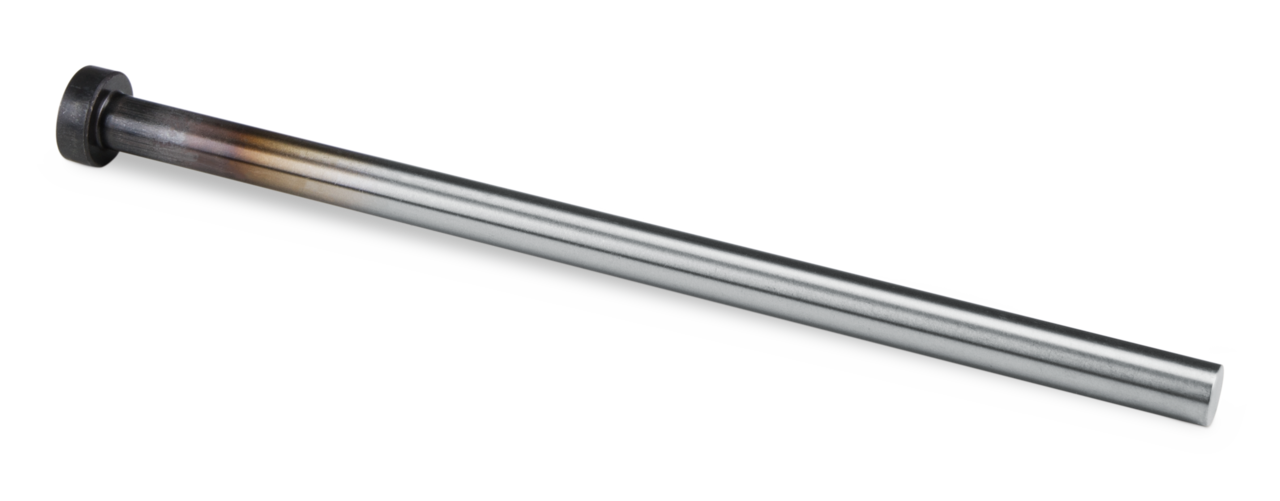

E 1730

- Material: 1.2343

- Heat treatment: nitrided - oxidation coated

- Shape: round, offset

E 1755

- Material: 1.2343

- Heat treatment: nitrided - oxidation coated

- Shape: flat

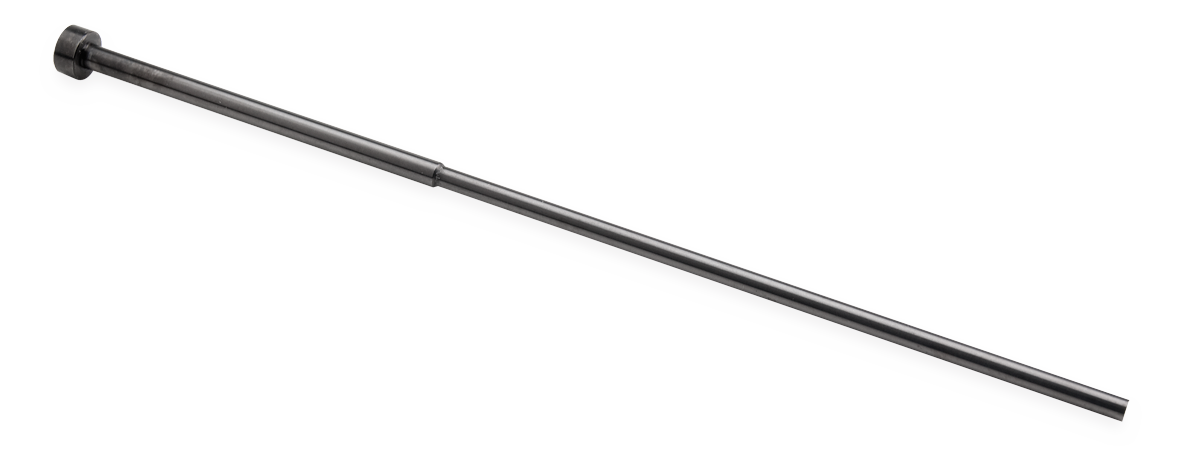

E 17103

- Material: HSS 1.3343

- Heat treatment: through-hardened

- Shape: round

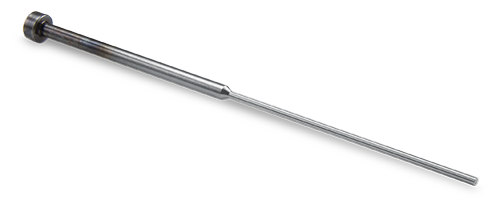

E 1742

- Material: 1.2343

- Heat treatment: non-nitrided

- Shape: round

E 1741

- Material: 1.2343

- Heat treatment: nitrided

- Shape: round

E 1750

- Material: 1.2343

- Heat treatment: nitrided

- Shape: round, sleeve

Efficient finishing of ejector pins and core pins

The innovative GMT 6000 Cutting and grinding machine enables efficient finishing of ejector pins, cutting punches, as well as many other components.In just one work step the workpiece is shortened with allowance and ground preciselyto the desired length. The robust design of the machine guaranteesexact length and angle tolerances with repeatable accuracy in consistentquality.

PRECISION CUTTING AND GRINDING MACHINE GMT 6000

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]