购物车 {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} 物料 更换购物篮

备注

| 图片 | 物料 | 件数 | 单价 | 总价 | 总价,含折扣 | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

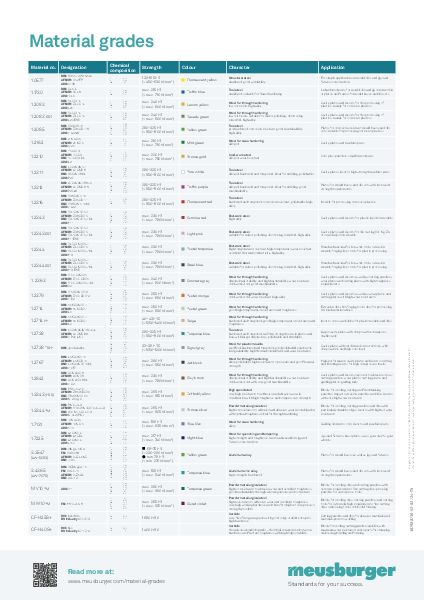

在我们挑选出的产品系列中,您几乎可以找到满足任何应用要求的材料。

1.2379 Steel for through hardening

Designation

| DIN: | X 153 CrMoV 12 |

| AFNOR: | Z 160 CDV 12 |

| UNI: | - |

| AISI: | ≈ D2 |

Chemical composition:

| C | 1.53 |

| Si | 0.30 |

| Mn | 0.35 |

| Cr | 12.00 |

| Mo | 0.80 |

| V | 0.80 |

Strength:

max. 255 HB

(≈ max. 860 N/mm²)

Thermal conductivity at 100 °C:

21 W/m K

Character:

high-alloy steel for through-hardening with moderate machinability; extremely wear resistant and low warpage, good dimensional stability, toughness and through hardenability

Application:

mould plates and inserts as well as wear plates and cutting dies with increased wear resistance

Treatment by

Polishing:

possible when hardened

Nitriding:

very well suited, due to the fact that the hardness of the base material will not fall below 60 HRC

EDM:

possible, Structure eroding not possible

Hard chroming:

possible

Etching:

not possible, coarse carbides are washed out

Heat treatment:

Soft annealing:

800 to 850 °C for about 2 to 5 hours; slow controlled cooling of 10 to 20 °C per hour to about 600 °C; further cooling in air, max. 235 HB

Hardening:

1020 °C

1060 to 1080 °C

quenching in oil/air/hot bath

obtainable hardness: 63−65 HRC

Tempering:

slow heating to tempering temperature (to avoid forming of cracks) immediately after hardening; triple tempering at max. secondary hardening temperature is recommended; rapid cooling following the tempering improves the dimensional stability; maximum hardness achievable after tempering: 60-62 HRC

Annealing graph:

Technical tip:

- secondary hardening, very good base material for nitriding or coating

Available in the web shop as:

Data sheet 1.2379

公司

Quick Links

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

P-Standard plates

P-Standard plates Standard bars

Standard bars NP-Precision bars

NP-Precision bars NR-Round bars

NR-Round bars NE-Blocks for eroding

NE-Blocks for eroding

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]