Kontakt

Vi ger personlig service från måndag till fredag, från 8:00 till 17:00. Via den här länken hittar du kontaktpersonen för din region.

Huvudkontor Wolfurt

+43 5574 6706-0

Varukorg {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Artikel Ändra varukorg

Anmärkning

| Bild | Artikel | St | Enhetspris | Totalpris | Totalt pris inklusive rabatt | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Kunder

- Mould making

- Die making

- Maskin- och fixturbygge

- Konstruktörer

- Formsprutare

- Produkter

- Företag

- Karriär

- Service

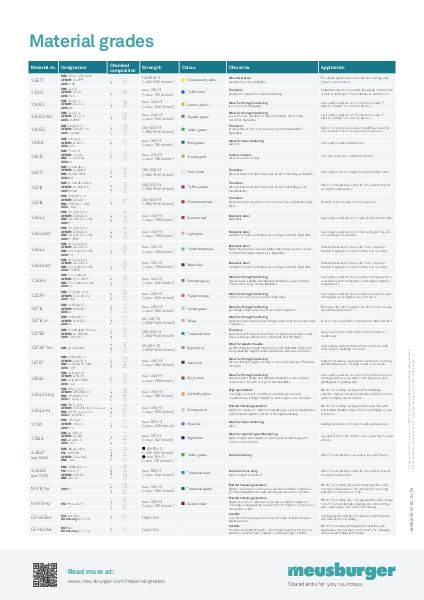

I vårt stora sortiment finns lämpligt material för nästan alla användningsfall.

M W10PM powder metallurgical steel

DESIGNATION:

EN: HS 10-2-5-8

INDICATORY ANALYSIS:

| C | 1.6 |

| Cr | 4.8 |

| Mo | 2.0 |

| V | 5.0 |

| W | 10.5 |

| Co | 8.0 |

Strength:

max. 285 HB

(≈ max. 970 N/mm²)

THERMAL CONDUCTIVITY AT 100°C:

26 W/m K

CHARACTER:

High-speed steel produced by powder metallurgy with highest compressivestrength, high adhesive wear resistance and excellent toughness, very high workinghardness possible

APPLICATION:

Blocks for eroding, dies, cutting punches and cutting tools for extremely highrequirements, fine blanking punches, embossing tools, cold solid forming

TREATMENT BY:

Polishing:

best metallurgical properties for mirror finish

Nitriding:

highly suited for nitriding

EDM:

highly suited

Coating:

highly suited

HEAT TREATMENT:

Soft annealing:

870 to 900°C for about 2 to 5 hours

slow controlled cooling inside the furnace 10 to 12°C per hour to about 550°C,

further cooling in air, max. 300 HB

Hardening:

curing temperature: see tempering chart

quenching in oil/compressed gas/air/hot bath

obtainable hardness: 68 HRC

Tempering:

slow heating to tempering temperature (in order to avoid formation of cracks)

immediately after hardening;

keep at tempering temperature for at least 1 hour

four tempering cycles are recommended, with cooling to room temperature in

between

TEMPERING CHART:

TECHNICAL TIP:

- Retains hardness at high temperatures due to highcobalt content

- Excellent for PVD and CVD coating without risk ofdimensional changes, as the steel is tempered atmore than 520°C

Available in the web shop as:

Data sheet M W10 PM

Företag

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2023 Meusburger

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

NE-Blocks for eroding

NE-Blocks for eroding

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]