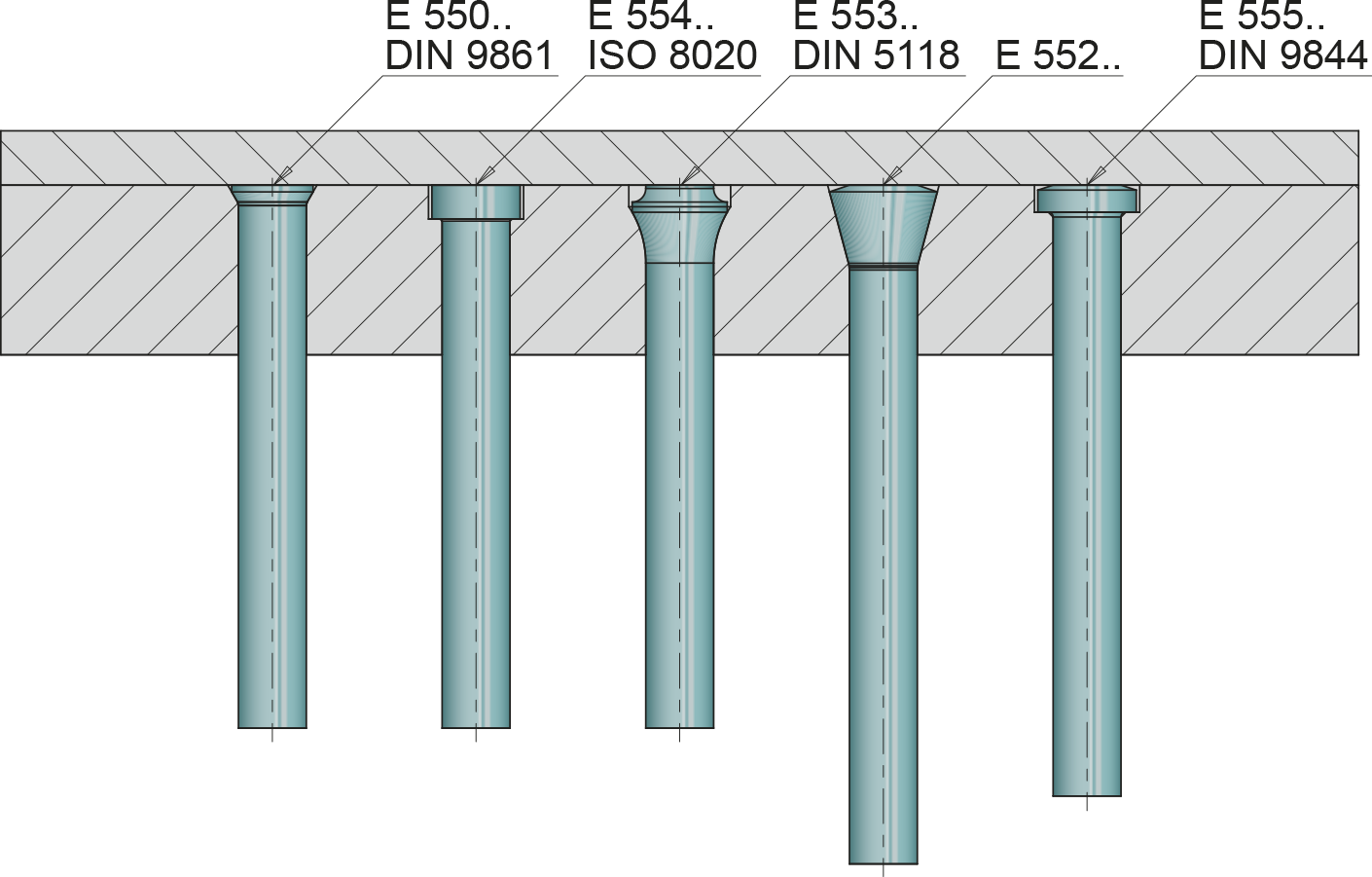

Attachment via the head geometry

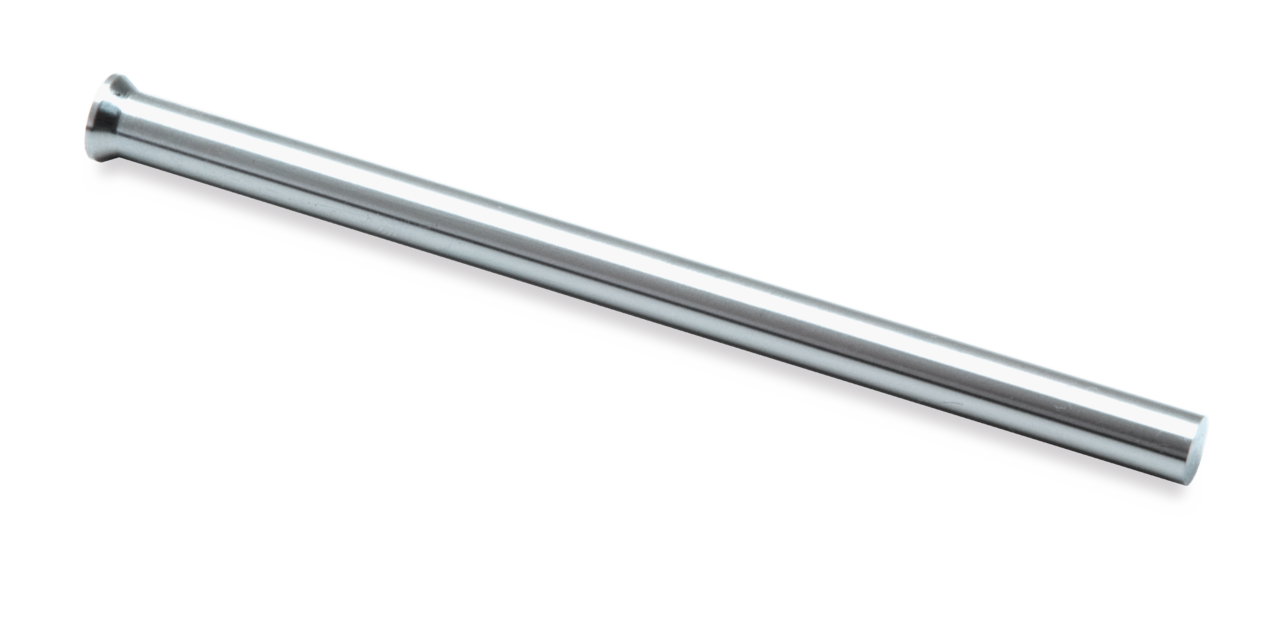

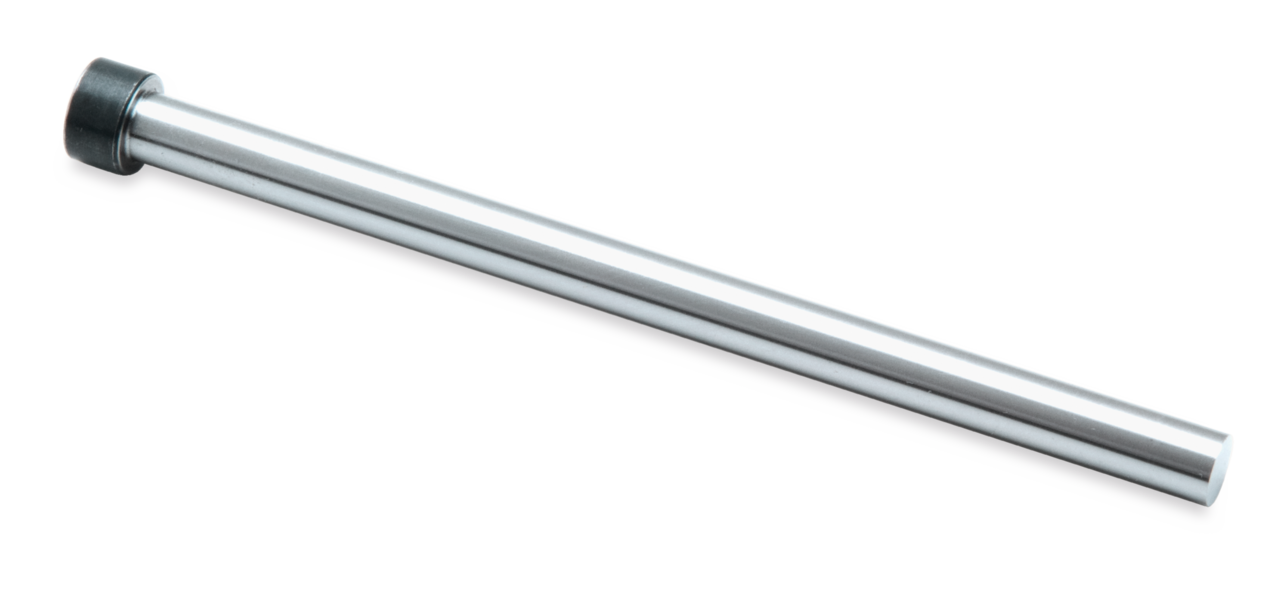

With this type of attachment, the cutting punch is clamped between the wear plate and the punch retainer plate via the head. The most commonly used shapes are conical, cylindrical and bottle-neck head shapes. The choice of shapes depends on the punching and retracting forces, expected service life and space available. The most common type, the cutting punch with conical head according to DIN 9861, has the advantage of requiring little space. The cutting punch with cylindrical head according to ISO 8020 requires a little more space, but allows for easier installation and withstands greater retracting forces. This punch is also optionally available from Meusburger ready-to-use with exact head height (E 55405), which saves the effort of grinding over the head.

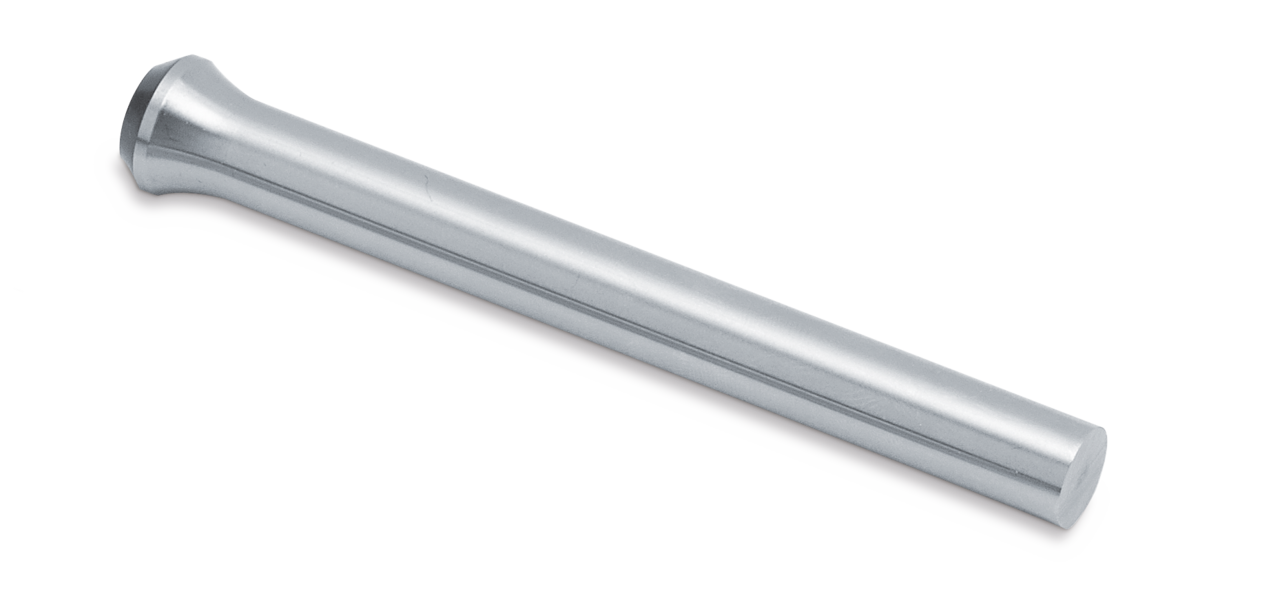

The cutting punch with bottle-neck according to DIN 5118 or the cutting punch with 30° conical head are suitable for very high retracting forces. Even though the cutting punch with bottle-neck requires less space, it requires a complicated retainer which can be introduced using an HSS counterbore tool (WZB 318128) or a mounting sleeve (E 55301). The cutting punch with cylindrical head according to DIN 9844 has a head height of 4 mm independent of the head diameter, which can simplify installation. All variants are readily available as standard parts from Meusburger.

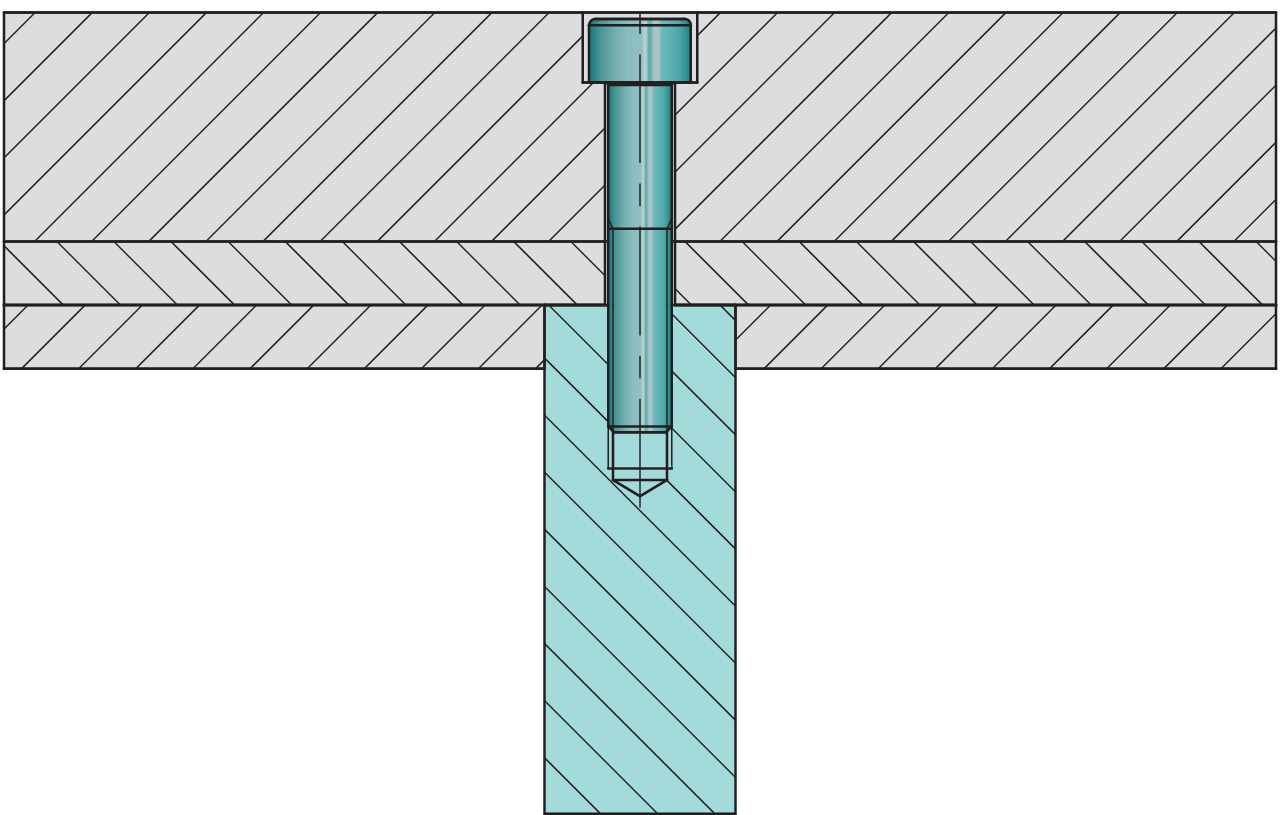

Screwed in cutting punches

The cutting punch is screwed to the head plate via a flange or a fixing hole on the front end.

For wire EDM contour punches, this fixing option allows for relatively simple production of the punch. In addition, thanks to the small space requirement, it is possible to place the cutting punches close together. It is also easy to underlay the cutting punches for height compensation after regrinding.

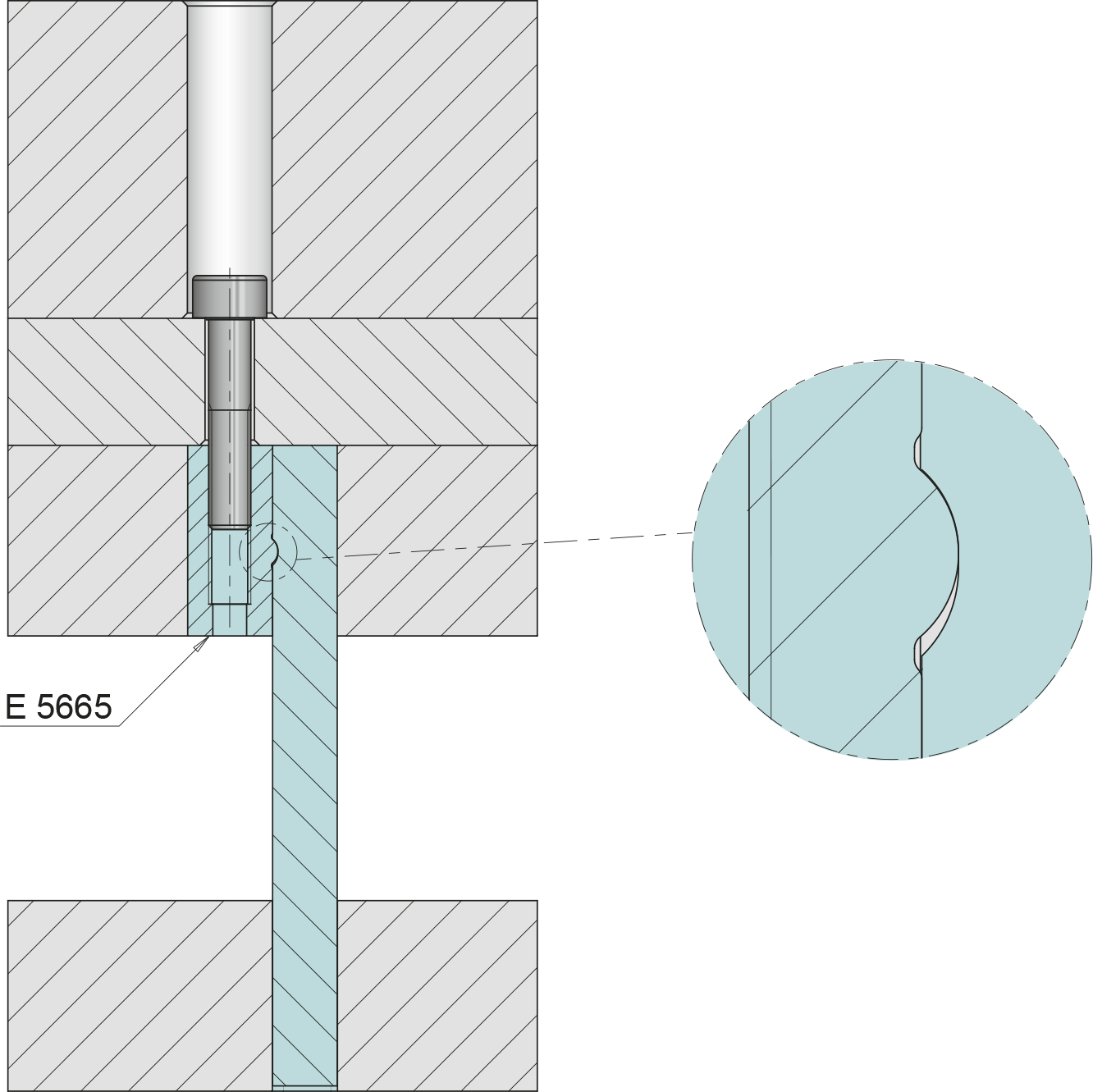

Positive locking connection via punch suspension piece

This attachment option is particularly suitable for filigree punches. Thanks to the standardised punch suspension piece, introduction of fixing threads in the punch is no longer necessary, and instead a radius contour is cut in. The bearing is floating in order to avoid unwanted forces on the punch. It is also easy to underlay the cutting punches here too. However, it must be ensured that both the punch and the retainer clip are underlaid so that the bearing of the punch is guaranteed to be floating.

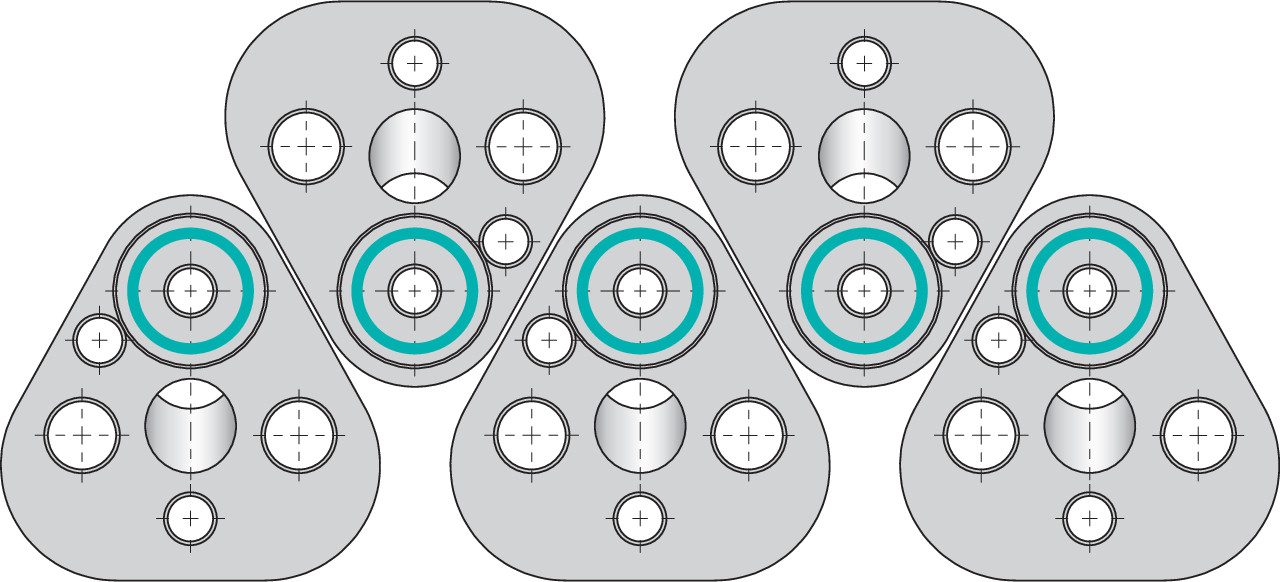

Quick-change system or ball-lock system

The characteristic feature of the quick-change systems or the ball-lock systems is a ball seat in the shaft of the punch. This is clamped in the punch retainer plate by a spring-loaded ball. To change the cutting punch, the ball is pushed back with a set screw and the punch can be quickly and easily removed. The set screw is then turned back to the starting position and the next punch is inserted. This eliminates the need to remove the entire retainer plate.

Quick-change systems are mainly used in the production area of the automotive industry. Due to the compact, triangular design, the space inside the stamping die can be optimally utilised. However, this type of punch attachment is not suitable for high stroke rates and high retracting forces. Alternatively, cutting punches according to ISO 8020 with the appropriate punch retainer plates are used here.

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

Ελλάδα [EL]

Ελλάδα [EL]

华 [ZH]

华 [ZH]