Kontakti

Na voljo smo vam od ponedeljka do petka med 8:00 in 17:00 uro. Na tej povezavi najdete kontaktne osebe za svojo regijo.

Centrala Wolfurt

+43 5574 6706-0

Košarica {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} izdelek Zamenjaj košarico

Opomba

| Slika | izdelek | Kos | Cene po pozicijah | Skupna cena | Skupna cena s popustom | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Stranke

- Mould making

- Die making

- Strojegradnja in izdelava priprav

- Za-konstrukterje

- Brizganje

-

Izdelki

- Novi izdelki

- Ohišja za forme

-

štančna ogrodja

- SV-Standardna ohišja

- SP-Precizna ohišja

- SH-Ohišje z dvema vodilnima stebroma zadaj

- Plošče za SD-Ohišje z dvema vodilnima stebroma diagonalno

- SZ-Ohišje z dvema vodilnima stebroma na sredini

- Plates for SM-modular concept

- SB-OHIŠJA ZA PREOBLIKOVANJE PLOČEVINE

- Programska oprema Offline-trgovina

- P-Plošče

- N-PALICE STANDARDNE

- Plošče in palice

- Izdelava po naročilu

- E-Vgradni elementi

- Toplokanalna tehnika

- Regulacija toplokanalnih sistemov

- Vse za delavnico

- Podjetje

- Zaposlitev

- Servis

Zanimate se za naše podjetje in naše izdelke? Potem ste tukaj pravilno.

Successful standardisation begins in the design phase

05.12.2018, Die making

The world is becoming smaller – both logistically and economically. Globalisation increases the competitive pressure on die and mould makers, but also offers the chance to profit from orders in fast-growing markets. At the same time the innovation wheel is turning ever faster, which requires adaptability and flexibility from companies. The high cost and time pressure forces companies to constantly improve their efficiency. A high degree of standardisation along the entire process chain offers an excellent opportunity to drastically reduce costs and project lead times.

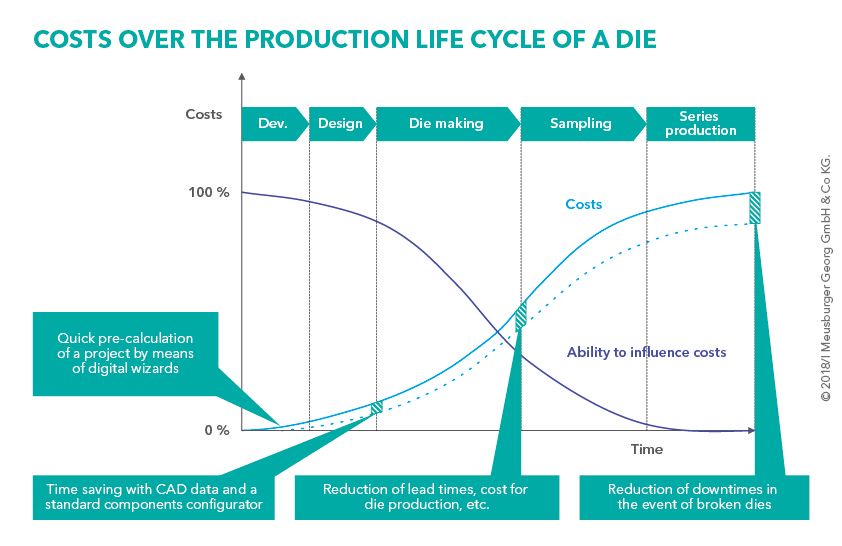

In the product life cycle of a die, it is important to take a holistic view of the costs. At the beginning of a project, possible savings should already be considered. The use of standard parts has a positive effect on the overall cost. Helpful questions are for example: are there die components which can be standardised? If so, what possibilities are there to fall back on for internally standardised parts or die set concepts? Could these be bought from an external standard parts manufacturer? There is a lot of savings potential here to gain clear competitive advantages.

The design phase is decisive

The costs of a die can be greatly influenced during the development phase, whereas towards the end of the process, in the series productions stage, it is almost impossible to reduce costs. The designer determines the machining sequence in the die. He or she decides how the individual machining stations or the feed are designed. In this phase, the production parameters with which the die will later work in the stamping workshop are set. In addition, the designer decides whether the die set is to be constructed from standard plates in stock or from order-specific special plates. The more standard parts used, the higher the percentage of fixed calculable costs.

Reach your goal quickly with digital wizards

The use of standard parts results in savings in all areas. This starts with the fast and reliable pre-calculation by means of the Meusburger die set wizards. With these tools, all necessary components for a project can be assembled quickly and easily and saved for later use. CAD data of complete die sets can be exported from the Meusburger web shop or offline shop to all common CAD systems with just a few clicks. This gives the designer more time to concentrate on the actual 'critical points' of a die.

Over 40,000 items to guarantee success

In the area of die making, Meusburger offers over 40,000 items, which are specially tailored to customer requirements. The low deformation material itself has a big influence on the manufacturing and maintenance costs of the die: thanks to the high-grade steel, which is heat-treated for stress relief, as well as exact form and position tolerances, subsequent costs can be reduced. Also the built-in components - such as active parts - perform important functions in the die. Buying these from external suppliers, rather than producing them in-house, offers significant additional savings and therefore long-term competitive advantages. The best time for putting this into practice is quite simply - now! Times of economic boom are exactly the right time to prepare for the future.

TIPS & TRICKS FOR STANDARDISATION

• Create quality standards through low deformation plates

• Develop design guidelines

• Reduce the variety of components used

• Use standardised components and lower manufacturing costs

• Create machining guidelines, such as predefined tolerances or dimensions

• Create standardised processes

Press contact

Should you require further information on this press release or have any questions or comments, please feel free to contact us by email.

Lia Klimmer

Head of Department Communications+43 5574 6706-1446

Podjetje

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]