Kontakti

Na voljo smo vam od ponedeljka do petka med 8:00 in 17:00 uro. Na tej povezavi najdete kontaktne osebe za svojo regijo.

Centrala Wolfurt

+43 5574 6706-0

Košarica {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} izdelek Zamenjaj košarico

Opomba

| Slika | izdelek | Kos | Cene po pozicijah | Skupna cena | Skupna cena s popustom | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Stranke

- Mould making

- Die making

- Strojegradnja in izdelava priprav

- Za-konstrukterje

- Brizganje

-

Izdelki

- Novi izdelki

- Ohišja za forme

-

štančna ogrodja

- SV-Standardna ohišja

- SP-Precizna ohišja

- SH-Ohišje z dvema vodilnima stebroma zadaj

- Plošče za SD-Ohišje z dvema vodilnima stebroma diagonalno

- SZ-Ohišje z dvema vodilnima stebroma na sredini

- Plates for SM-modular concept

- SB-OHIŠJA ZA PREOBLIKOVANJE PLOČEVINE

- Programska oprema Offline-trgovina

- P-Plošče

- N-PALICE STANDARDNE

- Plošče in palice

- Izdelava po naročilu

- E-Vgradni elementi

- Toplokanalna tehnika

- Regulacija toplokanalnih sistemov

- Vse za delavnico

- Podjetje

- Zaposlitev

- Servis

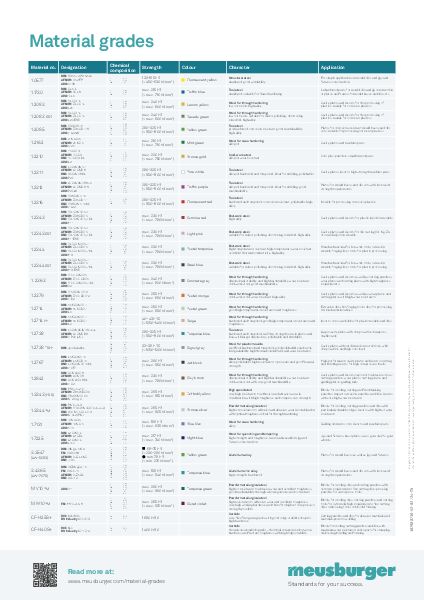

Naš izbran nabor omogoča za skoraj vsak primer uporabe ustrezen material.

1.3344 Powder metallurgical steel

Designation

| DIN: | PM 6-5-3 |

| AFNOR: | X 130 WMoCrV 6-5-4-3 |

| UNI: | W 6 Mo 5 Cr 4 V 3 |

| AISI: | M 3-2 (PM) |

Chemical composition:

| C | 1.25 |

| Si | 0.30 |

| Mn | 0.30 |

| Cr | 4.00 |

| Mo | 5.00 |

| V | 3.00 |

| W | 6.20 |

Strength:

max. 265 HB

(≈ max. 905 N/mm²)

Thermal conductivity at 100 °C:

24 W/m K

Character:

powder metallurgy high-speed steel with good machinability, high resistance to adhesive and abrasive wear, with optimal toughness due to the uniform and fine carbide structure, very good through hardenability and high dimensional stability

Application:

blocks for eroding, cutting punches and dies with particularly durable edges; inserts with highest wear resistance

Treatment by

highly suitable:

Mirror polishing, nitriding, EDM, coating

Heat treatment:

Soft annealing:

860 to 880 °C for about 2 to 5 hours

slow controlled cooling of 10 to 20 °C per hour to about 600 °C; further cooling in air, max. 260 HB

Hardening:

— 1180 °C

--- 1150 °C

-·-· 1100 °C

curing temperature: see tempering chart

quenching in oil/compressed gas/air/hot bath

obtainable hardness: 64−66 HRC

Tempering:

Slow heating to tempering temperature (in order to avoid formation of cracks) immediately after hardening;

tempering three times is recommended

Annealing graph:

Technical tip

- excellent for PVD and CVD coating; highest dimensional stability because the steel was tempered at more than 520 °C.

Available in the web shop as:

Data sheet 1.3344 PM (PM23)

Podjetje

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

NE-Blocks for eroding

NE-Blocks for eroding

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]