Contact

Vă stăm la dispoziție personal cu cea mai mare plăcere de luni până vineri între orele 8:00 și 17:00. Pe acest link ve-ți regăsi persoana de contact din regiunea dumneavoastră.

Centrala Wolfurt

+43 5574 6706-0

Coş de cumpărături {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Articol Schimbare coș cumpărături

Observație

| Poză | Articol | Buc | Preț unitar | Preț total | Preț total incl. reducere | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Clienți

- Mould making

- Die making

- Mașini și dispozitive

- Proiectanti

- Matrițer

-

produse

- Noutăţi produse

- Carcase de matrițe

-

Carcase de ștanțe

- Carcase standard SV

- Carcase de precizie SP

- Carcase SH cu două coloane, ghidaj în spate

- Carcase SD cu două coloane, ghidaj diagonal

- Carcase SZ cu două coloane, ghidaj central

- Plates for SM-modular concept

- ȘTANȚE DE DECUPARE ȘI FORMARE SB

- H 3000-Sistem de centrare şi fixare rapidă

- Plăci P

- BARE STANDARD N

- Plăci şi bare

- Prelucrare specială

- Accesorii E

- Sisteme calde

- Controler sistem cald

- Scule și consumabile

- Întreprinderea

- Carieră

- Service

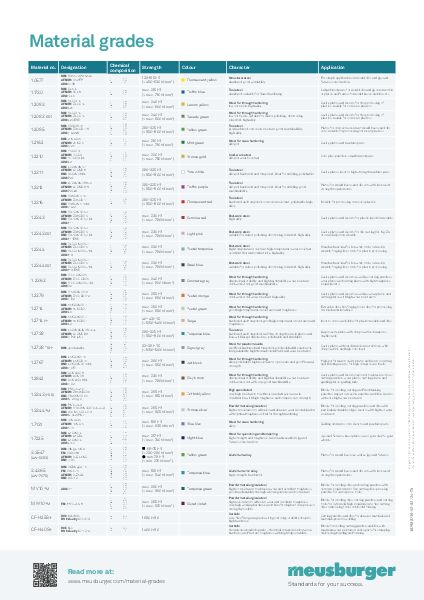

Sortimentul nostru bine selectat are materialul potrivit pentru aproape fiecare aplicație.

1.2842 Steel for through hardening

Designation

| DIN: | 90 MnCrV 8 |

| AFNOR: | 90 MV 8 |

| UNI: | 90 MnVCr 8 KU |

| AISI: | ≈ O2 |

Chemical composition:

| C | 0.90 |

| Si | 0.20 |

| Mn | 2.00 |

| Cr | 0.40 |

| V | 0.10 |

Strength:

max. 230 HB

(≈ max. 780 N/mm²)

Thermal conductivity at 100 °C:

33 W/m K

Character:

steel for through-hardening with good machinability and high wear resistance; low warping and high dimensional stability; with high toughness and through hardenability (uniform hardness for cross sections 40 mm)

Application:

cavity plates and inserts exposed to abrasive stress; cutting punches; wear plates, cutting dies and guiding plates; guiding rails

Treatment by

unusual:

Polishing, etching, nitriding » 1.2379

is possible:

EDM, hard chroming

Heat treatment:

Soft annealing:

680 to 720 °C for about 2 to 5 hours; slow controlled cooling of 10 to 20 °C per hour to about 600 °C; further cooling in air, max. 220 HB

Hardening:

790 to 820 °C

Quenching in oil/hot bath

Obtainable hardness: 63-65 HRC

Tempering:

slow heating (to avoid forming of cracks) to tempering temperature immediately after hardening; tempering twice with intermediate cooling down to 20 °C increases the steel's toughness

max. obtainable hardness after tempering: 58−60 HRC

Annealing graph:

Technical tip:

- Steel grade 1.2510 is an adequate alternative with regards to its properties, machinability and dimensional stability after heat treatment

Available in the web shop as:

Data sheet 1.2842

Întreprindere

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

N-Standard bars

N-Standard bars NP-Precision bars

NP-Precision bars NR-Round bars

NR-Round bars

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]