Contato

Estamos sempre disponíveis de segunda a sexta-feira, das 8:00 às 17:00. Utilize esta ligação para encontrar as suas pessoas de contacto consoante a sua região.

Sede em Wolfurt

+43 5574 6706-0

Carrinho de compras {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Artigos Mudar carrinhos de compras

Observação

| Imagem | Artigos | Unid. | Preço individual | Preço total | Preço total, incl. desconto | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Clientes

- Mould making

- Die making

- Construção de máquinas e gabaritos

- Projetistas

- Moldes de injeção

-

Produtos

- Artigos Novos

- Estruturas standard

-

Estruturas para cunhos e cortantes

- Placas SV para cunhos e cortantes

- Placas SP para cunhos e cortantes

- Placas para estruturas SH com duas guias, guiamento traseiro

- Placas para estruturas SD com duas guias, guiamento na diagonal

- Placas para estruturas SZ com duas guias, guiamento central

- Plates for SM-modular concept

- CONJUNTOS DE FORMAÇÃO

- Sistema de fixação H 3000

- Placas P

- Barras N

- Placas e barras

- Maquinação Especial

- Acessórios E

- Sistemas de canais quentes

- Controladores de temperatura

- Equipamentos e consumíveis

- Empresa

- Recrutamento

- Serviço

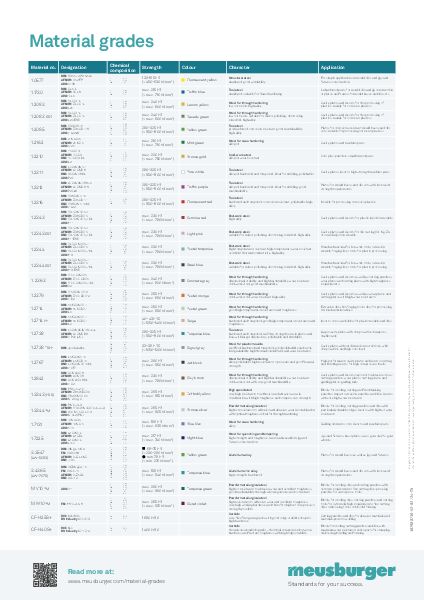

Na nossa gama selecionada, pode encontrar o material adequado para praticamente qualquer aplicação.

1.2162 Steel for case-hardening

Designation

| DIN: | 21 MnCr 5 |

| AFNOR: | 20 MC 5 |

| UNI: | - |

| AISI: | 5120 |

Chemical composition:

| C | 0.21 |

| Si | 0.25 |

| Mn | 1.25 |

| Cr | 1.20 |

Strength:

max. 210 HB

(≈ max. 710 N/mm²)

Thermal conductivity at 100 °C:

38.5 W/m K

Character:

standard steel for case-hardening with good machinability; high surface hardness with tough core

Application:

machine parts and moulding plates with a high surface hardness;

synthetic resin press moulds for the processing of thermoplastics and thermosetting plastics.

Treatment by

possible:

Polishing, etching, EDM

Nitriding:

Usually, hardened parts are not nitrided → loss of hardness.

Hard chroming:

recommended, results in increased wear and corrosion resistance

Heat treatment:

Soft annealing:

670 to 710 °C for about 2 to 5 hours

slow controlled cooling, further cooling in air, max. 205 HB

Carburising:

900 to 950 °C. The choice of the carburising means and carburising temperature depends on the desired surface carbon content, the carburising graph and the required case depth.

Application:

870 to 930 °C in powder/salt bath, cooling in oil/warm bath at 160 to 250 °C

Intermediate stress-relieving heat treatment:

630 to 650 °C, about 2 to 4 hours with slow furnace cooling

Preheating:

350 °C depending on dimensions

Hardening:

curing temperature 810 to 840 °C in oil of ~ 60 °C warmth

Cooling:

down to about 100 °C in oil, then in air to about 50 °C

Tempering:

1 hour per 20 mm part thickness, at least 2 hours

Annealing graph:

Technical tip:

- For mirror polishing we recommend the steel for through hardening 1.2767.

Para a visão geral do fabrico de moldes To the die making overview

Available in the web shop as:

Data sheet 1.2162

Empresa

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

Quick Links

@ 2023 Meusburger

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

P-Standard plates

P-Standard plates Standard bars

Standard bars

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]