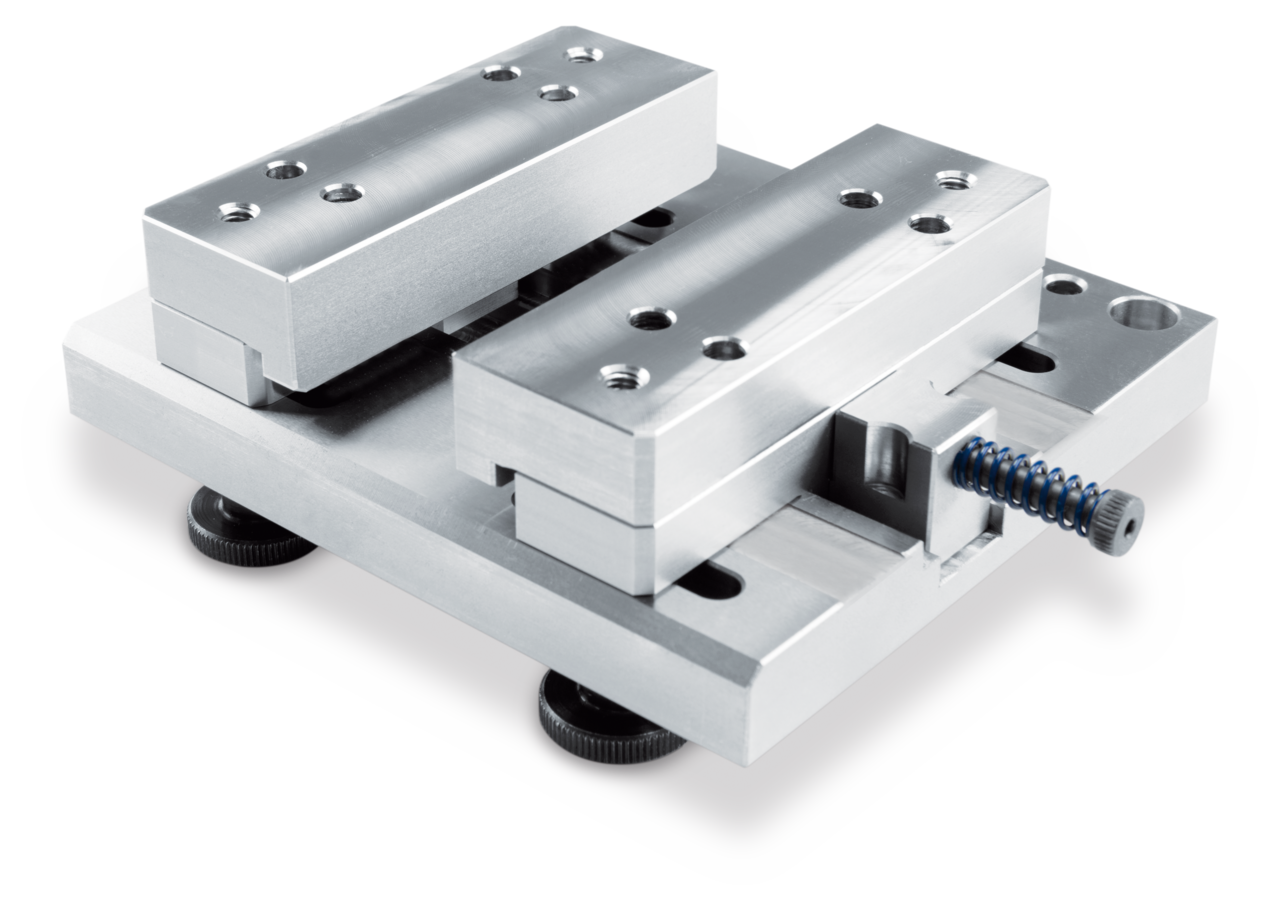

The strip guiding is carried out on both sides by means of high-quality needle roller bearing and the spring-loaded bearing on one side which allows free of play guiding. The spring force can be adjusted via three different system compression springs which are included in the delivery.

Types of installation

Version with E 56204 Mounting flange

Version without E 56204 Mounting flange

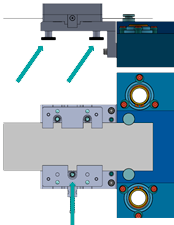

Adjustment of the infeed guide

Push the guides to the outside

Insert the strip into the strip guiding and fix the feed on the machine

Push the E 5624 Guiding unit with fixed bearing onto the strip as far as it will go and fix it there

EITHER:

Push the E 5623 Guiding unit with spring-loaded bearing against the strip (needle bearing touches the strip) and fix the screws (for a maximum strip width tolerance of +1mm)

OR:

Pull the spring-loaded needle in the opposite direction of the spring and set the preload (max. 0.5mm) with a feeler gauge or precision gauge tape (for a maximum strip width tolerance of ± ).

Push the E 5623 Guiding unit with spring-loaded bearing against the strip (needle bearing touches the strip), fix the screws and remove the setting tool.

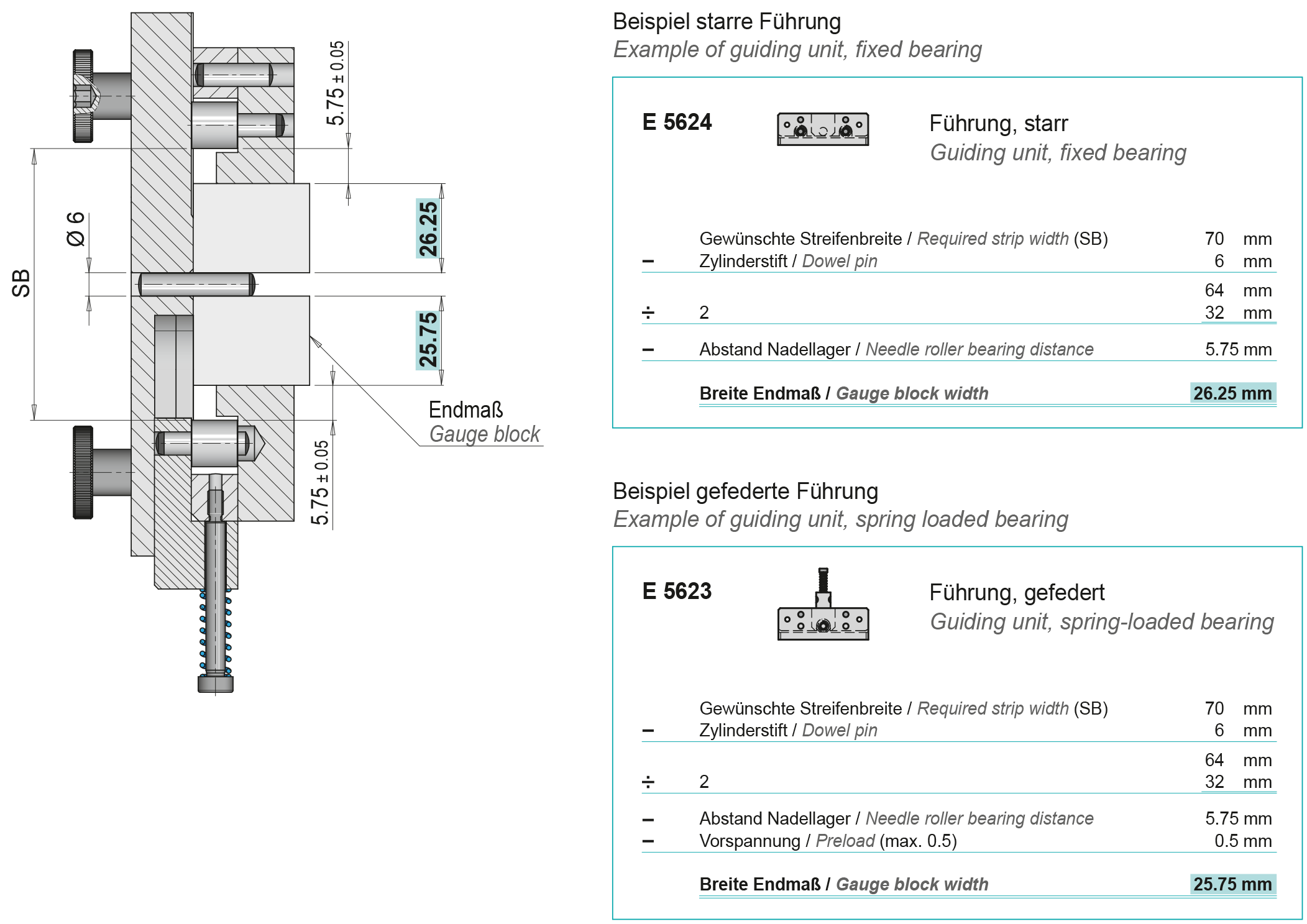

Adjustment of the infeed guide with the help of the reference holes

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]