Pocket – Removing EDM scale

There are a few options for removing the EDM scale of a pocket. We show you an uncomplicated way here.

Lateral draft angles

The lateral draft angles of the pocket can be easily worked on with a ceramic fibre stone in combination with the GESU 1200 ultrasonic polisher with up to 45 W output.

Bottom surfaces

The Easy Lap System and the classic polishing stones are very suitable for removing the EDM scale on bottom surfaces. For perfect results and easy use we recommend our premium air files.

To guarantee optimum cutting performance of the Easy Lap stones, cutting fluids should be used.

Recesses – Mirror finish polishing

Mirror finish polishing is the first class of polishing. All surfaces are flawless at the end of this polishing. Again, there are several ways to achieve the best result.

The requirements for polishing can vary greatly – from merely glossy surfaces with perhaps micro scratches, to completely scratch-free high gloss surfaces.

Step 1 – Preparation

Before the actual polishing, the surface can be preworked with a V 76709 brass fibre felt bob with shank . This preparation simplifies and shortens the further steps.

Step 2 – Polishing

In the next step, the classic polishing felt with diamond compound and polishing oil/thinners are used. Start with a 25 μm or 17 μm grit, depending on how clean the surface already is. This way, you slowly work down to 3 μm.

Step 3 – Finishing

Finally, the surface is polished again by hand with the 3 μm diamond compound or diamond fluid and a premium cleaning cloth .

Information

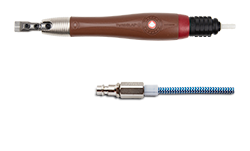

Our polishing felt products are best operated with the GESM 1000 and the matching micro motor .

Radius – Fine polishing

Not every radius can be treated the same way. That is why we also offer a wide range of accessories for this field of application and provide you with optimal support during treatment.

Our wide range of polishing points are popular for fine polishing. Additionally, we also like to use our abrasives such as the flap wheels.

If the radius has a certain Rz value, as is often the case for the stamping area, this is usually machined with silicon carbide abrasive paper.

For perfect machining at the right speed for the polishing point and flap wheel, we recommend our GESM 1000 and the matching micro motor.

Discover our wide range of products for your surfaces

Polishing points with rubber bond

The polishing points with rubber bond are ideal for polishing and fine grinding steel, rust, acid-resistant steel, and high-temperature materials such as non-ferrous metals.

Thanks to the special quality of these polishing points, they can also be used with lubrication materials. With other polishing points, the pores would seal such materials, making them unusable.

These polishing points can be used for matt polishing as well as for applying optical effects. Due to the elastic integration of the grit, a very fine polish can be achieved.

Application area: grooves, holes, concave and convex surfaces

V 72522

Polishing points, medium rubber bond, shank Ø 3

V 72523

Polishing points, hard rubber bond, shank Ø3

V 72532

Polishing points, medium rubber bond, shank Ø 6

Polishing stones

There is a suitable polishing stone for every surface and material to be polished.

In our range, you will find selected polishing stones that we recommend especially for the removal of EDM scale .

The ideal polishing stones for different materials

Depending on the material and application, different polishing stones are needed to achieve optimal results.

Tool steel

Aluminium

Non-ferrous

Stainless steel

The polishing stones are often used in combination with our polishing stone holders and air files.

Easy Lap

The basis of the Easy Lap System is a rectangular polishing stone with a corresponding small base area and a push rod. Due to the hinged arm connection of these components in the working direction the polishing stone lies flat on the surface of the work piece. The relatively small base area in connection with the push rod allows the required working pressure for optimal material removal.

Polishing felt products

Our polishing felt products are available in various designs and shapes:

- Soft, medium and hard

- With brass fibres for more material removal

- With shank, as rod or ring with velcro

Control unit for M-Line micro motor

To use the polishing felt products optimally and with the correct speeds, we recommend the GESM 1000 control unit. Due to the top selection of different handpieces, a variety of different surfaces can be processed.

Finishing

Diamond compounds are produced in different grades, ranging from the simplest industrial diamonds that are sieved with a wide mesh and produced in very low concentration up to high-grade, highly concentrated diamonds.

Cleaning

For cleaning sensitive surfaces, we recommend using a lint and dust-free cleaning cloth.

Polishing brushes

The right polishing brush is important for the desired result, material, and area of application.

Chungking bristles, black/white

- Stiff, sturdy bristles

- Good absorbency for pastes

Goat hair bristles

- Elastic, soft bristles

- For finishing

Nylon bristles

- Especially suited for the food processing industry

- For finishing

Brass wire

- Leaves a smooth grinding pattern

- May leave stains on the surface of the workpiece

- For rust or scale removal

Steel wire

- Flexible and elastic

- Makes a plainly visible grinding pattern

- For scale removal and deburring

INOX stainless steel wire

- Corrosion resistant steel wire

- Flexible and elastic

- Makes a plainly visible grinding pattern

- For scale removal and deburring

Speed Lap

THE MEUSBURGER SPEED LAP SYSTEM

The Speed Lap system consists of pads and bars for applying diamond compounds in order to achieve high surface quality and save time.

- New compound material

- Prevents the formation of washouts and built-up edges

- Higher material removal rate compared to other methods

- Reacts less sensitively to applied pressure

- Enables uniform, scratch-free lapping

- Sturdy lapping bars

Technical information

PREPARING THE LAPPING PADS

Before using the lapping pads for the first time, use a fine abrasive paper or diamond foil to hone them.

PREPARING THE LAPPING BARS

Adjust the lapping bars to the geometry to be machined - this is possible with sanding discs, abrasive paper or files; round lapping bars can be held in a collet chuck for this purpose.

GRIT SIZES

The optimum grit size is 6 μm, but coarser grit sizes are also possible. If necessary, lapping can be carried out to 3 µm.

LUBRICATION

Dilute the diamond compound with some VLM 5 cutting fluid or VLM 20 polishing oil.

PRESSURE

Apply light pressure during 60-70% of the work step, finish for the rest of the time, i.e. work without pressure.

DRIVEN PROFILER

Speed: 4,000 - 7,000 min-1

Stroke length: 0.5 - 1.0 mm

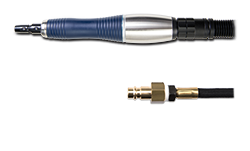

Air files

In order to work quickly and efficiently, we offer our premium air files with a stroke of 0.15 – 10 mm.

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]