Composition and characteristics of a DLC coating

The coating is largely made up of the chemical element carbon. It consists of an adhesive coat and a carbon coat.

- DLC coating thickness:≈ 2 μm

- Hardness:≈ 3000 HV

- Colour: black grey

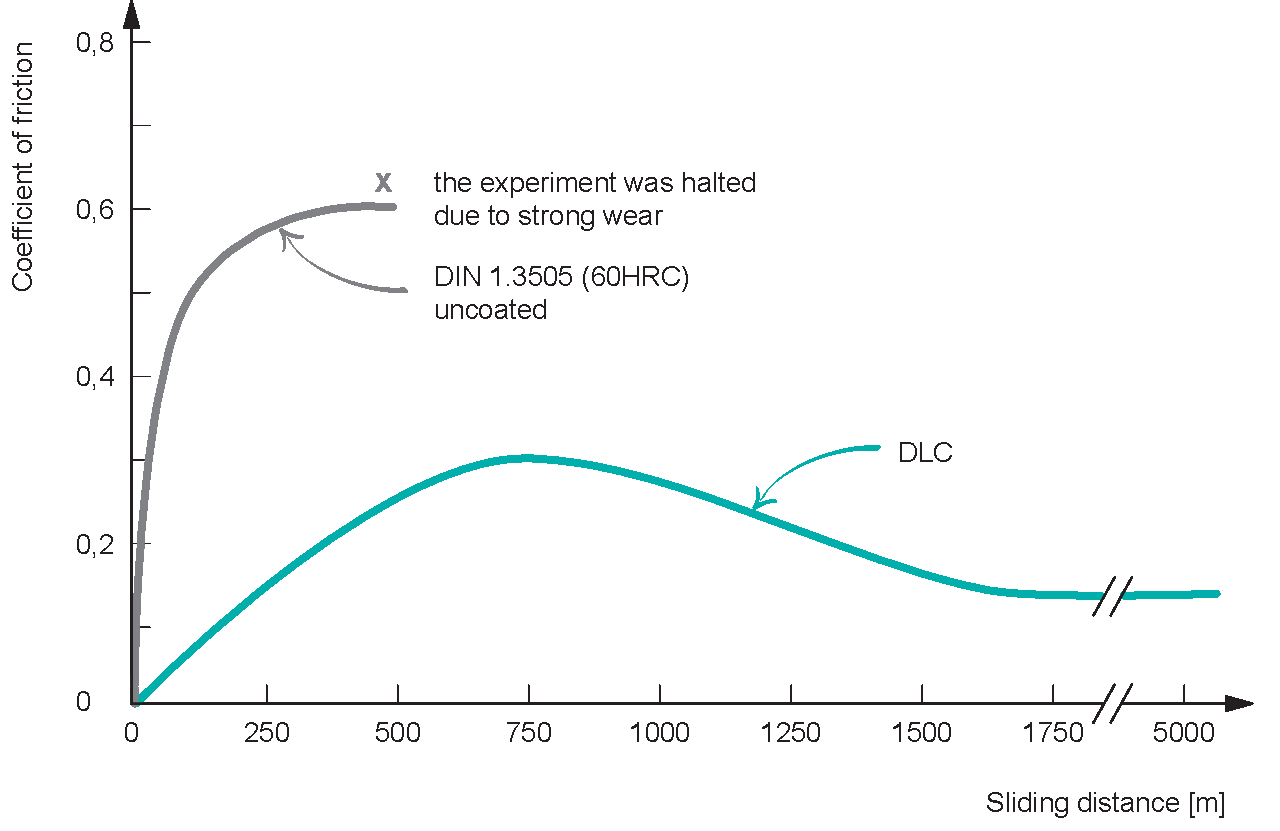

- Coefficient of friction against steel: 0.1 – 0.15

Areas of application for DLC coated Meusburger standard components

Guiding and locks

Guiding elements and particularly locks endure high wear through the friction from the opening and closing of the mould. The DLC coating offers the best sliding properties and minimises adhesive wear. This ultimately lengthens the intervals between lubrication and leads to a longer service life for the mould.

Slides

Lubrication close to the cavity often leads to grease residues on the plastic part. Thanks to the best dry-running properties of DLC coated sliding surfaces, lubrication in these areas can be left out completely.

Ejectors

Targeted lubrication of ejectors can be quite tedious thanks to the often limited accessibility. This can lead to a lack of lubrication and ultimately to fretting of the ejectors. DLC coated ejectors are the ideal way to avoid this, thanks to their excellent dry-running properties and high corrosion resistance. These are also optimal prerequisites for use in a cleanroom.

Components for demoulding

In order to meet the high mechanical demands of the switching elements on latch locks, these are DLC coated. This enables an even longer service life.

Due to the DLC coated sliding elements, the maintenance intervals for lubrication for two-stage ejectors is lengthened from 100,000 strokes to 300,000 strokes.

Our conclusion:

DLC coated standard components are slightly more expensive, but the investment quickly pays off through higher productivity.

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]